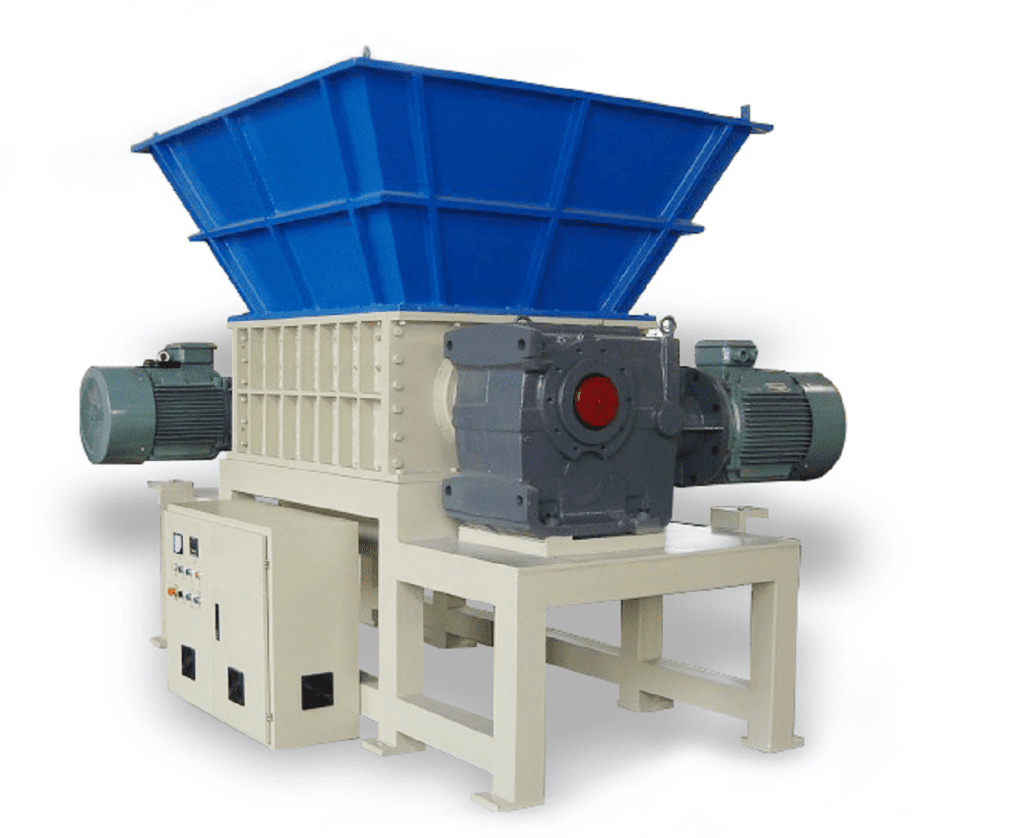

Introducing the SHREDALL Two Shaft Shredder Machine: a game-changer in recycling and resource recovery. Its dual-shaft design ensures unparalleled efficiency in breaking down various materials, from plastics to metals, with uniform shredding. Versatile and robust, these machines maximize throughput and productivity while ensuring long-lasting performance. Upgrade your waste processing with the SHREDALL Twin Shaft Shredder Machine today!

The Working of Twin Shaft Shredder Machine

The SHREDALL Twin Shaft Shredder Machine operates with two shafts equipped with cutting blades that rotate in opposite directions, efficiently shredding materials fed between them. This counter-rotating motion enhances shredding efficiency, aided by variable speed and torque settings for optimal performance. Some models include screening and sorting mechanisms for size-based material separation. These versatile machines handle plastics, metals, wood, rubber, and electronic waste, making them essential for diverse recycling processes.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535 today to explore our range and get expert assistance.

Key Features

Introducing Dual Shaft Shredders: equipped with two parallel shafts and cutting blades rotating in opposite directions for powerful shredding. Operating at low speed but high torque, while robust construction ensures durability in industrial settings. Upgrade to Dual Shaft Shredders for versatile, efficient, and durable shredding solutions!

Shredding Material

they efficiently shred various materials like documents, e-scrap, wood scrap, tires, and more. Their variable particle size output suits different shredding needs

Shredding Machine Type

The “Dual Shaft Shredder” is a type of shredding machine designed for efficient material reduction.

Usage/Application

These machines can handle a wide range of materials, including paper, plastic, metal, wood, rubber, and electronic waste. They are commonly used in recycling plants, waste management facilities, and manufacturing industries for reducing the size of materials and facilitating their processing, recycling, or disposal. The actual applications and capabilities of a shredding machine may vary depending on its specific model and configuration. Always refer to the official product documentation for accurate information.

Capacity

With a shredder from 1000 kgs/hr to 10,000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country’s manufacturing prowess.

High Performance and Easy Installation

Twin Shaft or Dual Shaft Shredders, are renowned for their high performance. Operating at low speed but delivering high torque, they efficiently shred various materials like paper, plastic, metal, wood, rubber, and electronic waste. Designed for light-duty applications with a throughput of up to 1 ton per hour, they maximize productivity.

Product Description

The SHREDALL Two Shaft Shredder Machine is a groundbreaking innovation in the field of recycling and resource recovery. It features an advanced dual-shaft design that delivers unprecedented efficiency in breaking down a myriad of materials. This design ensures uniform shredding and allows the machine to handle various waste streams, including plastics, metals, textiles, and more

Contact Us

We are here to assist you. Feel free to Contact us:

- Email: Info@shredall.in

Phone: +91 9090003535

Conclusion

In conclusion, the SHREDALL Two Shaft Shredder Machine is a versatile and efficient solution for various shredding needs. Its advanced dual-shaft design, high throughput, and robust construction make it an ideal choice for recycling centers, waste management plants, and industries looking to optimize material recovery. Whether it’s processing plastics, metals, textiles, or more, this machine delivers superior performance and reliability. Always refer to the official product documentation for accurate information. This innovative machine truly represents a significant advancement in the field of recycling and resource recovery.