In the fast-changing world of recycling, businesses in the metal processing industry are constantly looking for ways to maximize their Return on Investment (ROI). One of the smartest strategies to achieve this is by investing in a top-tier aluminum shredder. At SHREDALLTM, we specialize in crafting advanced aluminum shredders that not only boost operational efficiency but also provide lasting value for years to come. In this detailed guide, we’ll walk you through the essential steps for setting up and operating an aluminum shredder, ensuring you get the most out of your investment.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Understanding Aluminum Shredders: Why Invest?

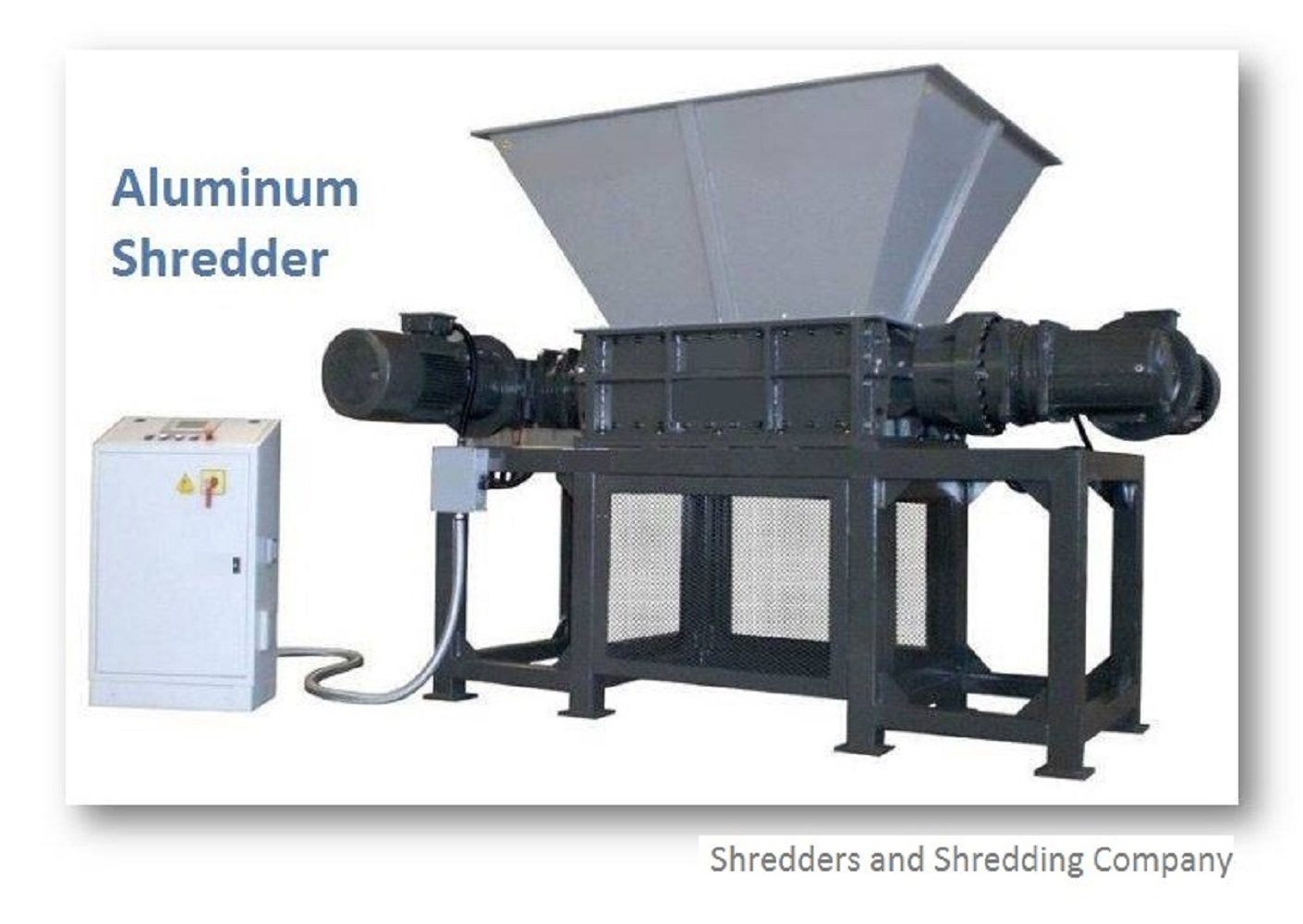

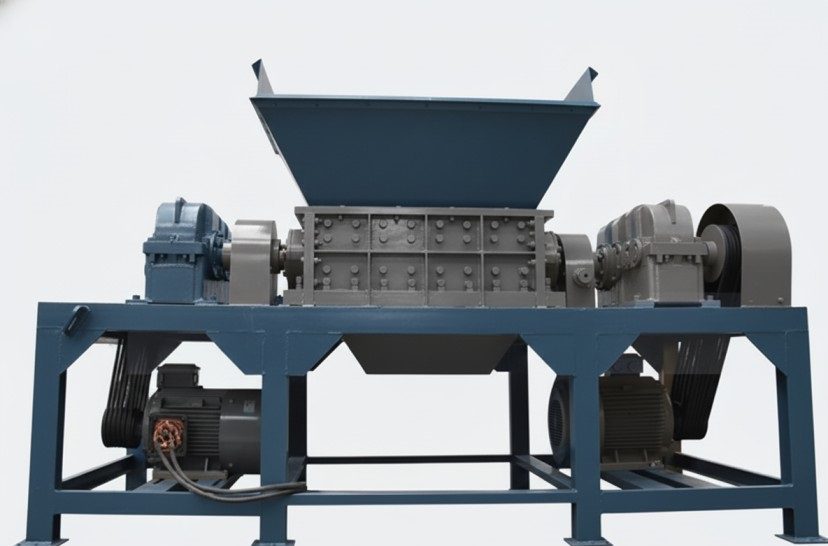

Aluminum shredders are essential equipment in the recycling and scrap metal industries. They are designed to break down large aluminum items such as old cars, industrial scrap, and aluminum packaging into smaller, more manageable pieces. The shredded aluminum can then be processed further, cleaned, and reused, resulting in a highly sustainable and profitable operation.

By investing in a high-performance aluminum shredder like those offered by SHREDALL, companies can:

- Reduce Material Size: Shredders break down aluminum waste into smaller particles, increasing processing efficiency.

- Increase Efficiency: Faster shredding times mean less downtime and higher throughput, which directly boosts productivity.

- Enhance Recyclability: Smaller aluminum pieces are easier to recycle and can be resold at a higher price.

- Lower Operational Costs: With the right shredder, businesses can reduce labor costs, material handling, and maintenance needs.

How SHREDALL Aluminum Shredders Maximize ROI

At SHREDALLTM, we take pride in providing aluminum shredders that deliver measurable results. Here’s how our shredders contribute to maximizing ROI:

1. Robust Design & Durability

Our shredders are built to last with durable materials and cutting-edge technology. The heavy-duty construction ensures that the shredder can handle tough materials over extended periods, which means less maintenance and fewer replacements, ultimately saving you money in the long run.

2. Energy Efficiency

SHREDALLTM aluminum shredders are designed to give high throughput. This makes your operations more cost-effective and environmentally friendly, contributing to long-term savings.

3. High Throughput

Our shredders are engineered for speed and efficiency. With faster shredding times and high output, SHREDALLTM machines can process larger quantities of aluminum in a shorter period. This increased throughput translates to higher production volumes and, ultimately, greater profits.

4. Customization Options

Every business has unique needs. At SHREDALLtm, we offer customizable shredding solutions that allow you to tailor the equipment to your specific requirements. This ensures that you can maximize the efficiency of your operation, reducing wasted time, materials, and energy.

5. Minimal Maintenance & Downtime

We understand that downtime costs money. SHREDALLTM shredders are designed for easy maintenance with user-friendly controls and fast troubleshooting. With regular maintenance, you can ensure that your shredder operates at peak performance for many years.

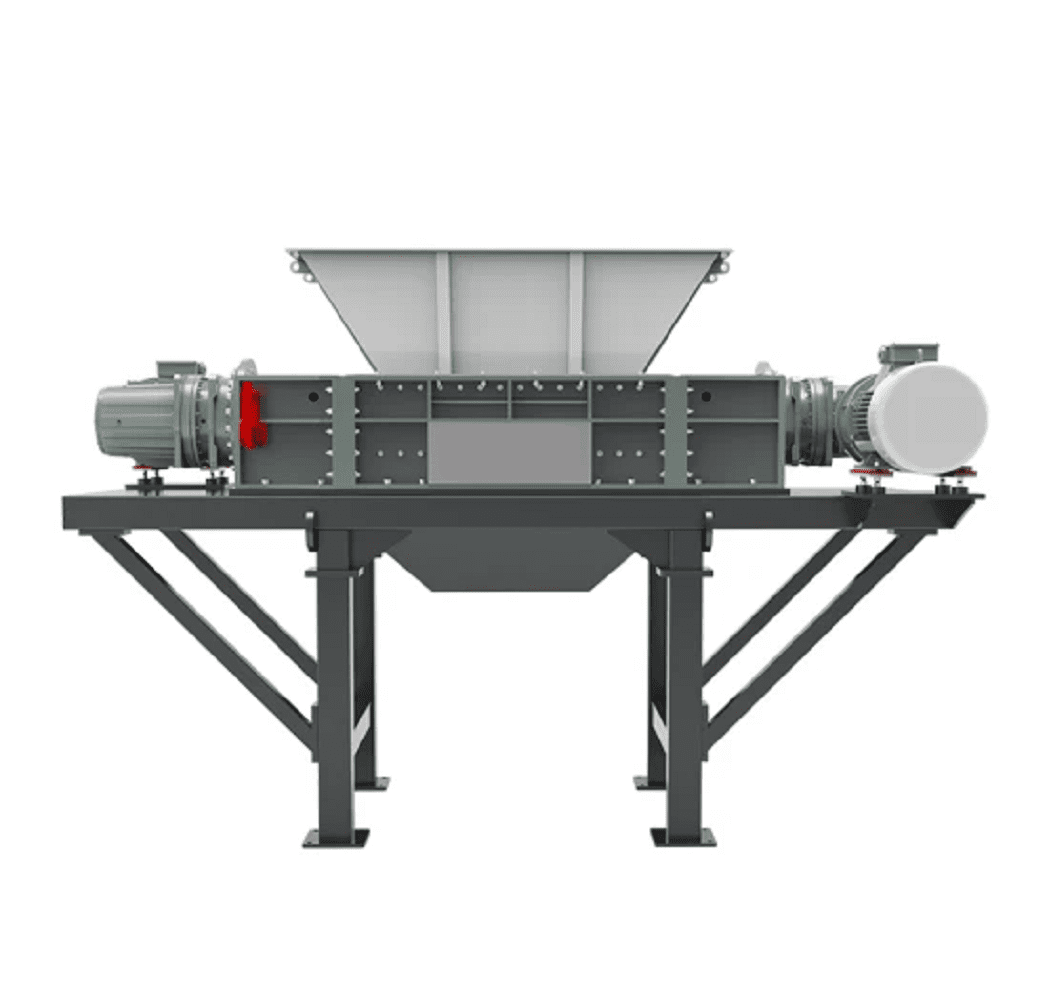

Aluminum Shredders

Setting Up Your SHREDALLTM Aluminum Shredder: A Step-by-Step Guide

Proper installation and setup of your aluminum shredder are crucial to maximizing its performance and lifespan. Here’s a simple guide to ensure your SHREDALLtm shredder is set up for success:

Step 1: Site Preparation

Before you receive your SHREDALL aluminum shredder, make sure you have a clean, level, and spacious area for installation. The machine will require ample room for airflow and access to necessary utilities like power and water (if required). A stable foundation ensures optimal performance and prevents unnecessary vibrations.

Step 2: Power Supply

SHREDALL shredders require a consistent power supply. Be sure that the electrical setup can handle the shredder power demands. This includes ensuring the appropriate voltage and amperage, and that all wiring meets local electrical codes.

Step 3: Installation of the Shredder

Once the shredder is delivered, follow these installation steps:

- Positioning: Place the shredder on its designated spot, ensuring adequate space for the input and output of materials.

- Connection: Connect the shredder to the power supply, ensuring that all safety switches and mechanisms are in place.

- Safety Checks: Conduct a full safety inspection to confirm that all guards, emergency stops, and safety features are operational before running the machine.

Step 4: Testing the Shredder

After installation, run the machine at low speeds to test the shredding process. Ensure the material is being fed in properly, and there are no unusual noises or vibrations. Gradually increase the operating speed to ensure the shredder works smoothly at full capacity.

Operational Best Practices for Maximizing ROI

Once your SHREDALLTM aluminum shredder is up and running, follow these operational tips to maximize efficiency and ROI:

1. Proper Material Sorting

Before feeding materials into the shredder, ensure they are properly sorted. Remove any non-metallic contaminants like plastic or rubber. This will reduce wear and tear on the shredder and increase the quality of the shredded material.

2. Regular Maintenance

Maintain a regular cleaning and maintenance schedule to ensure optimal performance. Regularly check blades, motors, and belts for wear and replace them as necessary. A well-maintained shredder will deliver peak performance and fewer repairs, helping to reduce operational costs.

3. Optimize Feeding Rates

Feeding too much material into the shredder at once can cause clogging and strain the motor, while too little material will waste energy. SHREDALL shredders are equipped with automated feeding systems, but understanding the optimal feeding rate for your materials can further improve efficiency.

4. Monitoring Performance

Monitor the performance of your shredder with real-time analytics, which many SHREDALL models offer. This data helps you track throughput, power consumption, and maintenance needs. With these insights, you can adjust your operations for maximum efficiency and cost savings.

5. Safety Protocols

Always adhere to strict safety protocols to prevent accidents. Ensure that operators are well-trained and that all safety guards and features are in place. A safe working environment minimizes downtime due to injuries and potential machine damage.

Conclusion

Investing in a high-quality aluminum shredder from SHREDALLtm is one of the best ways to maximize your return on investment in the recycling industry. By following the proper setup procedures and operational best practices, you can ensure that your shredder operates at peak efficiency, delivering optimal throughput, reducing downtime, and lowering costs.

At SHREDALL, we are committed to providing businesses with reliable, energy-efficient, and high-performance shredding solutions. Contact us today to learn more about how our aluminum shredders can help your business thrive.

About Us SHREDALL:

SHREDALL is a leading manufacturer of industrial shredding equipment, specializing in high-performance aluminum shredders. With decades of experience, our team is dedicated to providing reliable, energy-efficient, and customizable shredding solutions that maximize ROI for businesses across various industries.