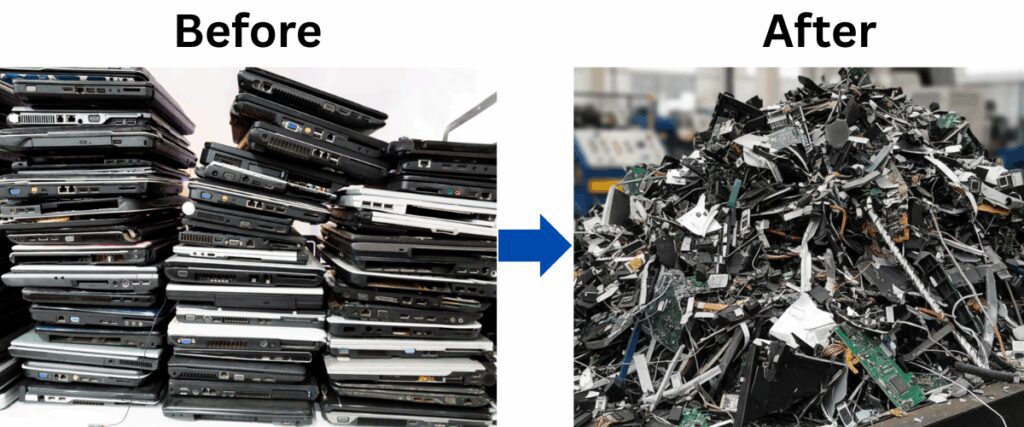

Laptops store critical data, valuable metals, and components that can be recycled—but they also pose environmental hazards if not disposed of properly. A Laptop Shredder, a specialized e-waste shredder machine, is the solution. It physically destroys laptop hardware—casing, hard drives or SSDs, motherboards, screens—so that data cannot be retrieved and materials can be recovered safely. For businesses, institutions, or recyclers, a reliable laptop shredder is essential for secure data protection, compliance, and sustainable value extraction.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Key Characteristics & How Laptop ShredallTM Shredders Work

- Pre-Processing Stage

- Remove batteries, screens (if needed), and external components.

- Drain any liquids (in rare devices with cooling, or cleaning agents).

- Disassemble parts that may interfere or cause hazards (e.g. lithium battery modules, which can be fire risks).

- Remove batteries, screens (if needed), and external components.

- Shredding Mechanism

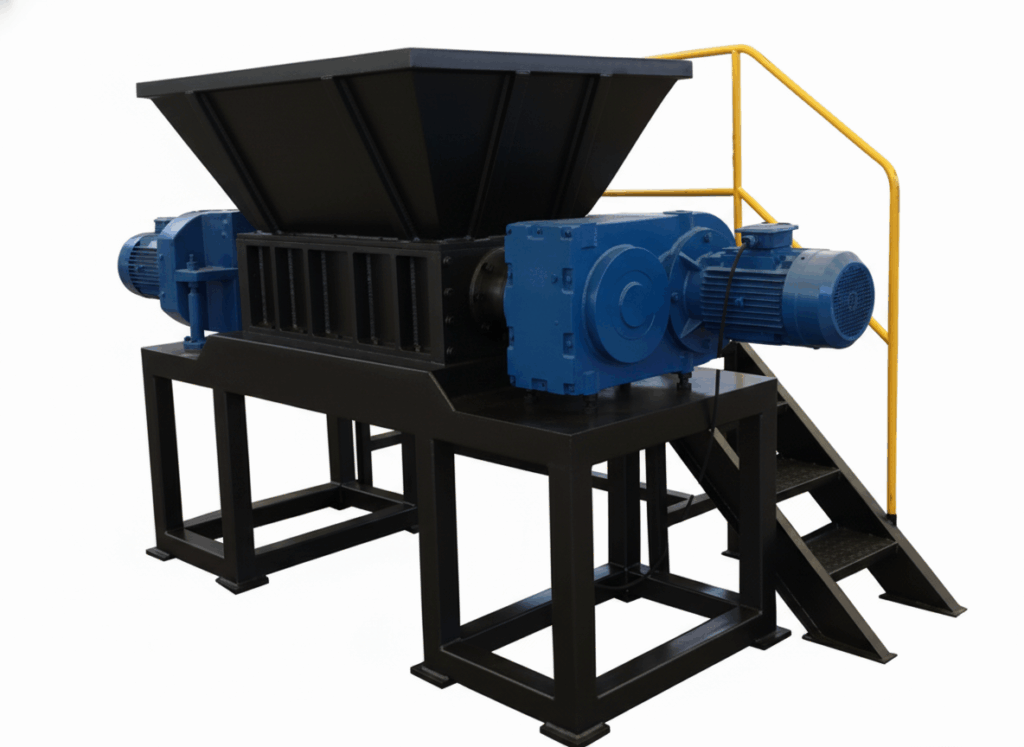

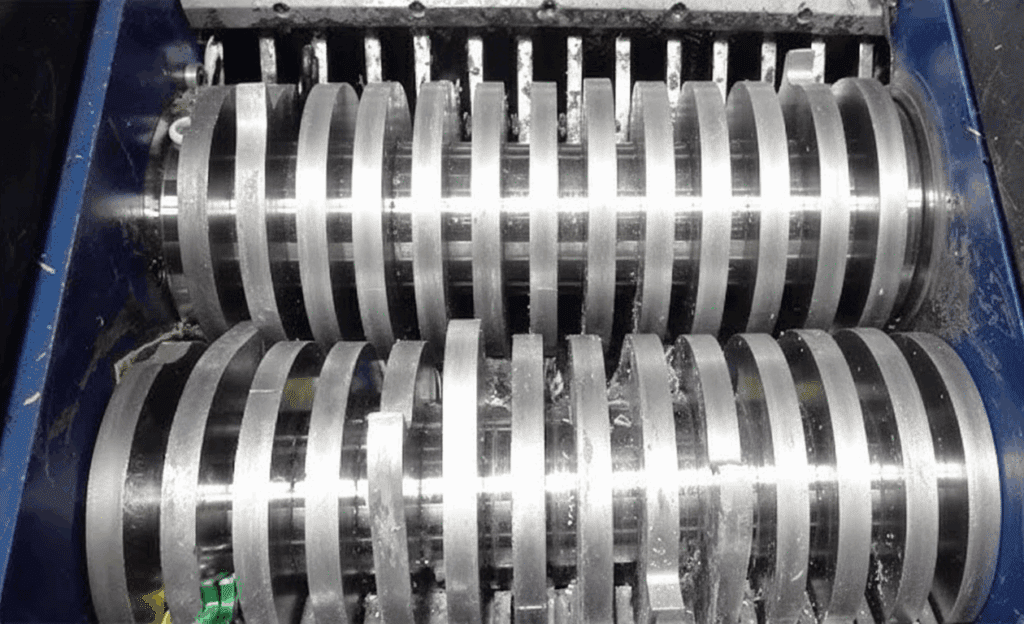

- Most laptop shredders use dual-shaft or multi-shaft heavy duty cutters/blades designed to cut through mixed materials: metals, plastics, glass.

- Blade thickness, spacing, speed & torque determine how fine the shredding is. Some machines aim for fragments small enough to hide or destroy data storage surfaces (HDD/SSD).

- Most laptop shredders use dual-shaft or multi-shaft heavy duty cutters/blades designed to cut through mixed materials: metals, plastics, glass.

- Size & Throughput

- The capacity depends on machine size, blade quality, motor power. Smaller units (tabletop or small industrial) may handle a few dozen laptops or hard drives per hour. Large industrial ones can handle hundreds of kg per hour. We also provide customized solutions as per What Size You Want.

- For example, some dual-shaft laptop/e-waste shredders offer 500-700 kg/hr throughput. Shredall E-Waste Shredder

- The capacity depends on machine size, blade quality, motor power. Smaller units (tabletop or small industrial) may handle a few dozen laptops or hard drives per hour. Large industrial ones can handle hundreds of kg per hour. We also provide customized solutions as per What Size You Want.

- Separation & Sorting Post-Shred

- Once shredded, fragments are run through separation processes:

- Magnetic separation for ferrous metals

- Eddy current or optical/NIR/XRF for non-ferrous metals (aluminum, copper)

- Sieving/screening to classify pieces by size, ensuring uniform output

- Magnetic separation for ferrous metals

- Hazardous materials (like some circuit board chemicals, battery parts) are removed or handled separately.

- Once shredded, fragments are run through separation processes:

- Safety, Data Security & Compliance

- Hard drives / SSDs are physically destroyed beyond repair—no risk of data recovery.

- Machines have safety features: guards, emergency stops, overload protection, and noise suppression.

- Compliance with e-waste, data protection, and environmental standards is important.

- Hard drives / SSDs are physically destroyed beyond repair—no risk of data recovery.

Typical Specifications You’ll Find

Here are some real-world spec ranges from existing laptop/e-waste shredders, so you can know what to aim for or compare against:

| Specification | Example Values |

| Blade thickness | ~12-20 mm depending on hardness of material (e.g. HDDs, plastics) |

| Number of blades | 20-30 blades in dual shaft cutters for higher throughput machines |

| Throughput | 200-700 kg/hr in medium/large industrial models |

| Feeding width / chamber dimensions | ~400-500 mm feed widths common for laptop shredders in industrial settings |

| Motor Power / Electrical Requirements | Between ~7.5 kW to 30-40 HP or more, depending on capacity and load. Dual shafts or heavy load designs demand higher power. |

Applications & Who Needs a Laptop Shredder

- Corporate / Government Offices: Destroy old laptops, desktops, hard drives to protect sensitive data.

- Institutions & Schools: When upgrading, ensuring that student / administrative data is obliterated.

- Data Centers & IT Disposal: Regular decommissioning of servers, storage devices, laptops.

- Electronic Recycling Centers: Full-scale e-waste processors need machinery capable of handling laptop hardware.

- Manufacturers of Electronics: Discarded / defective units / scrap in production lines need safe disposal and recycling.

Benefits of Using a Laptop Shredder

- Data Security: Once shredded, the storage devices cannot be accessed—critical for privacy, compliance (like GDPR, HIPAA etc.).

- Resource Recovery: Metals (copper, gold, silver, aluminium), plastics, and electronic components can be recovered and reused.

- Environmental Protection: Reduces e-waste in landfills; prevents toxic chemicals from circuit boards or battery units leaking into soil/water.

- Cost-Savings in Disposal: Shredded volume is smaller (lower transport, storage, handling costs).

- Regulatory/Legal Benefits: Helps meet e-waste laws and data protection regulations.

Challenges & What to Look For When Choosing a Laptop Shredder

| Challenge | Key Feature / Solution to Look For |

| Mixed material hardness & blade wear | Hardened steel blades, replaceable blades, high torque drive; dual or multi shaft; systems with automatic reverse or jam clearing. |

| Battery / hazardous components risk | Pre-processing to remove batteries; machines that can handle battery safety (spark suppression or inerting); proper disposal of removed parts. |

| Data security certification | Look for machines certified to certain destruction standards (e.g. NIST, DoD standards for HDD/SSD destruction) or able to achieve particle size that meets those standards. |

| Energy efficiency & operational cost | Efficient motors; machines that can run continuously without overheating; good cooling / ventilation; minimal downtime. |

| Safety & environmental compliance | Enclosures, dust / particulate filters, noise reduction; compliance with local e-waste regulations. |

Examples & Market Insights

- The ShredallTM dual-shaft e-waste shredder handles laptops, hard drives, PCBs etc., with ~500-700 kg/hr throughput and robust design.

- ShredallTM sells dual-shaft laptop/e-waste shredders with capacities from 700-1000 kg/hr; cutting widths of ~750 mm; heavy duty gears; auto-reverse features.

Conclusion

A high-quality laptop shredder is more than just a piece of machinery—it’s a tool for security, sustainability, and profitability. If you are dealing with old laptop hardware, hard drives, or any e-waste, investing in a reliable shredder (with good blade strength, safety features, adequate throughput, and compliance) makes sense. With rising regulatory attention, data breach risks, and environmental concerns, a laptop shredder is not optional—it’s essential.