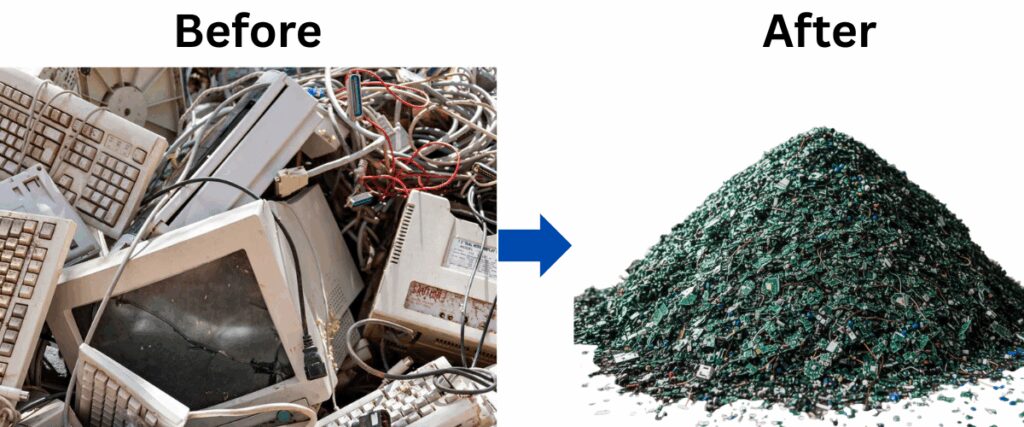

In a world overflowing with old computers, laptops, hard drives and electronic peripherals, responsible recycling is more important than ever. A computer shredder is not just a machine it’s a tool for safeguarding data, reclaiming valuable materials, and reducing environmental harm. ShredallTM computer shredder delivers industrial strength and precision, designed to handle the toughest e-waste while ensuring secure data destruction and maximum recovery value.

What Is a Computer Shredder?

A computer shredder (also called e-waste shredder) is an industrial or heavy-duty machine built to break down electronic devices like PCs, laptops, circuit boards, hard drives, keyboards, and cables into small, manageable fragments. The shredded material is then sorted to recover metals (copper, aluminium, steel), plastics, glass, and safe disposal of hazardous components. It also ensures that any sensitive data stored on devices is irreversibly destroyed.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Key Components & Working Principles

Here are the main parts and how the ShredallTM shredder works:

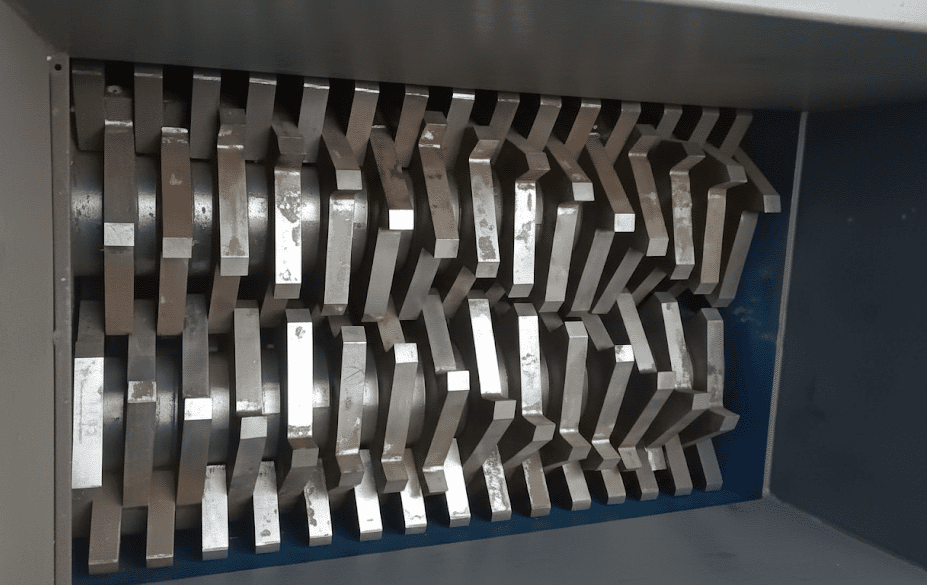

- Blades / Shafts or Rotor Assemblies: Often dual-shaft, multi-shaft, or rotor/hammers made of hardened steel. These blades are built to resist wear, impact, and heat when shredding dense electronics.

- Feed Hopper / Conveyor System: Devices are loaded via feeder or hopper, sometimes with conveyor belts for automated feeding.

- Motor & Powertrain: High torque motors (3-phase supply in many industrial machines) drive the blades. ShredallTM ensures efficient motors and gearbox design to maintain consistent shredding, especially for mixed materials.

- Control System: PLC (Programmable Logic Controller) or digital controllers oversee operations, protect against overload, manage blade direction reversal if jammed, monitor motor load, etc.

- Safety & Environmental Systems: Enclosures, guards, emergency stop buttons, containment of fluids or hazardous substances (e.g. batteries, capacitors), filtration of dust / particles, and compliance with relevant environmental and data-protection regulations.

Applications of Computer Shredders

ShredallTM computer shredder is suitable for:

- Secure destruction of data storage devices (HDDs / SSDs) from offices, financial institutions, government.

- Recycling centres that handle discarded computers, motherboards, printers, monitors etc.

- Electronic manufacturing waste rejects, scrapped components.

- Municipal e-waste collection programs.

- Refurbishers who want to destroy parts not usable or to remove data before resale.

Benefits of Using ShredallTM Computer Shredder

| Benefit | Description |

| Data Security | Hard drives & storage media are physically shredded so data cannot be recovered. |

| Maximised Material Recovery | Recover metals, plastics, and glass for resale or reuse; reduces reliance on raw materials. |

| Volume Reduction & Cost Savings | Smaller pieces mean lower shipping, storage, and disposal costs. |

| Environmental Compliance | Safely handle hazardous components (lead, mercury, cadmium), meet environmental laws, and reduce landfill. |

| Operational Efficiency | High throughput machines reduce labor, downtime; automated features & safety reduce risk. |

| Brand Reputation & Responsibility | Using proper e-waste recycling demonstrates corporate social responsibility and aligns with ESG mandates. |

Specifications & Performance Metrics (What to Look For)

To make sure you get a shredder that works well, especially from ShredallTM or any premium vendor, check specifications like:

- Throughput: how many kilograms/hour it can shred (e.g. small units might do 100-500 kg/hr; large industrial units up to tons/hr).

- Blade thickness, material, number of cutter teeth/shafts.

- Motor power: matched to capacity, with good torque so blades don’t stall on dense components.

- Feed size and opening dimensions.

- Output particle size and uniformity.

- Separation capabilities (magnetic, non-ferrous, optical).

- Safety & automation features (overload protection, reverse mechanism, emergency stops).

Real-World Examples & Industry Use

- ShredallTM multifunction electronic waste shredder processes circuit boards, cables, electronic components; capacities ranging from ~500 kg/hr to ~5,000 kg/hr. shredall.in

Challenges & How ShredallTM Addresses Them

| Challenge | Solution from ShredallTM |

| Mixed Material Hardness | Blades made of hardened steel; ability to reverse direction; dual shafts; robust frame. |

| Hazardous Components / Data Safety | Pre-processing protocols; secured hard drive destruction; safe extraction of batteries and capacitors. |

| High Energy Use & Wear | Efficient motors; variable speed drives; high torque designs; replaceable blade modules. |

| Environmental & Regulatory Pressure | Certifications; regular maintenance; emission/dust control; ensuring compliance with e-waste legislation. |

| Downtime & Maintenance | Spare part availability; remote monitoring; easy access for routine servicing. |

Future Trends in Computer Shredding & E-Waste Recycling

- Increased use of AI and automated sorting (vision systems, spectral imaging) before shredding, to improve purity.

- Demand for secure data destruction standards (e.g. standards for government / military).

- Modular and mobile shredders (units that can be moved to collection sites).

- Improved recycling of plastics and rare metals from PCBs.

- Stricter environmental regulations pushing for full lifecycle accountability.

Conclusion

A computer shredder is a cornerstone for any responsible e-waste management or data destruction operation. When built right—with strong blades, safety, high throughput, and separation capabilities, it delivers value, security, and sustainability. ShredallTM, investSing or offering high performance computer shredders means you’re enabling your customers to comply with laws, protect data, recover precious materials, and improve environmental footprints.