Aluminum Shredder vs Aluminum Crusher: Choosing the Right Equipment

When it comes to processing aluminum waste, two of the most commonly used machines are the aluminum shredder and the aluminum crusher. Both are designed to break down aluminum materials, but they operate differently and are suited to different needs. Understanding the key differences between an aluminum shredder vs aluminum crusher will help you choose the right equipment for your business, ensuring you maximize efficiency, save costs, and achieve the best results.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

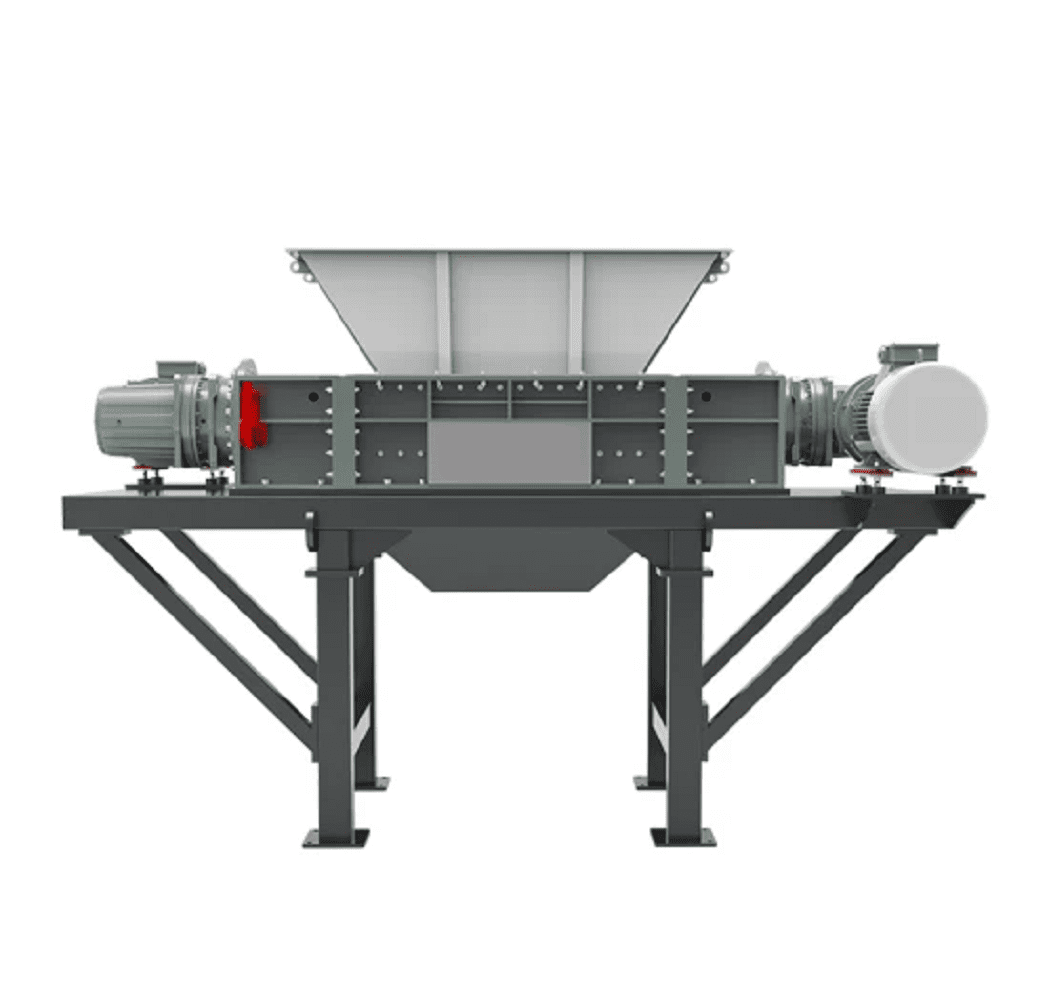

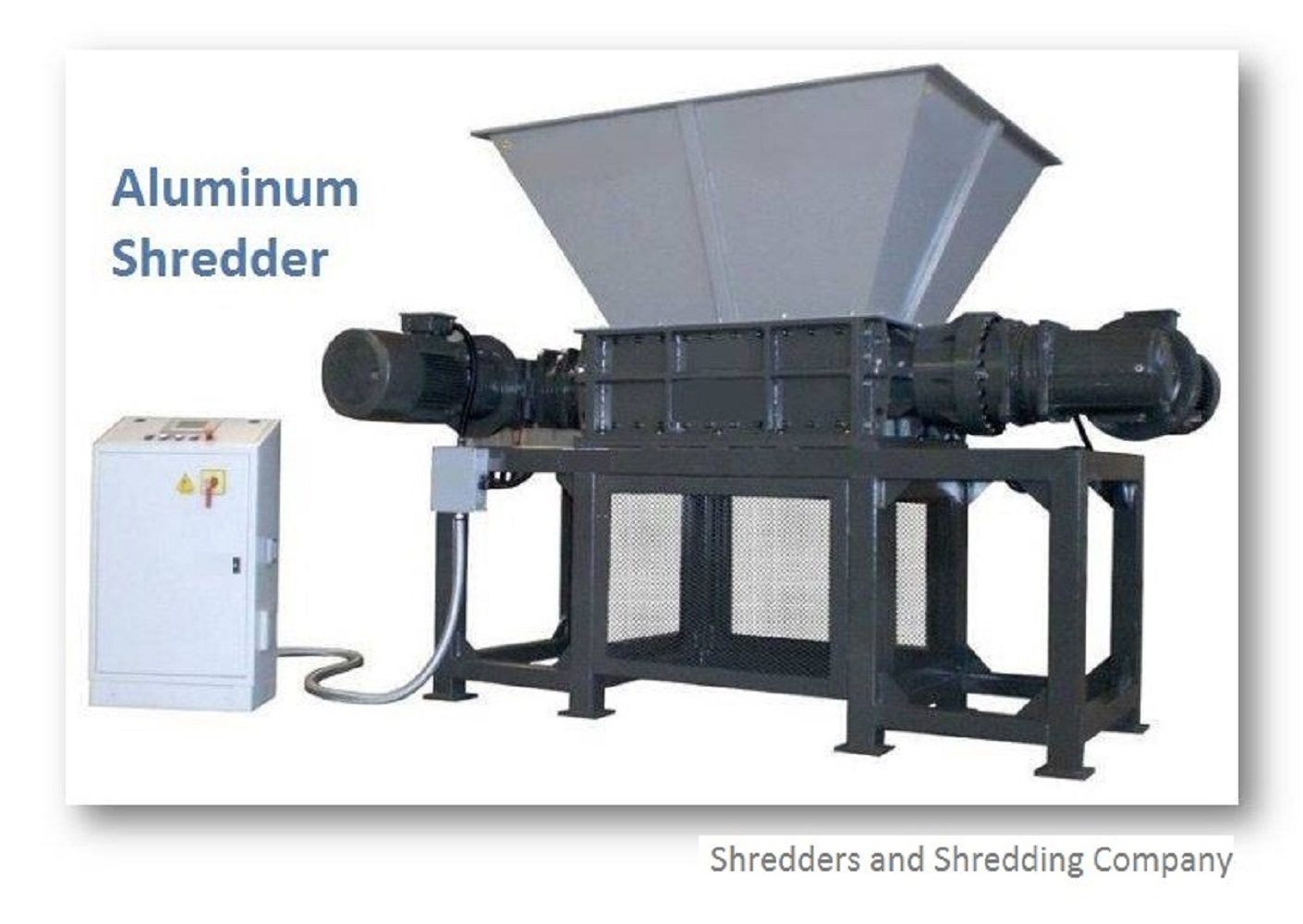

What Is an Aluminum Shredder?

An aluminum shredder is a heavy-duty machine designed to cut, shear, and tear aluminum materials into smaller pieces or chips. The shredder operates with a set of rotating blades that provide consistent force, breaking down aluminum scrap—such as cans, car parts, and industrial waste- into uniform-sized pieces. These small, manageable chips are then ready for further processing or resale.

List of Aluminum Shredders

What Is an Aluminum Crusher?

An aluminum crusher, on the other hand, typically uses a high-impact force to crush aluminum scrap into small fragments. Unlike shredders, which use blades to shear materials, crushers generally use a compressive or impact force to reduce aluminum to smaller, more compact pieces. Crushers are often used to crush aluminum cans, scrap metal, or large items into flat, easily manageable pieces that take up less space for storage or transport.

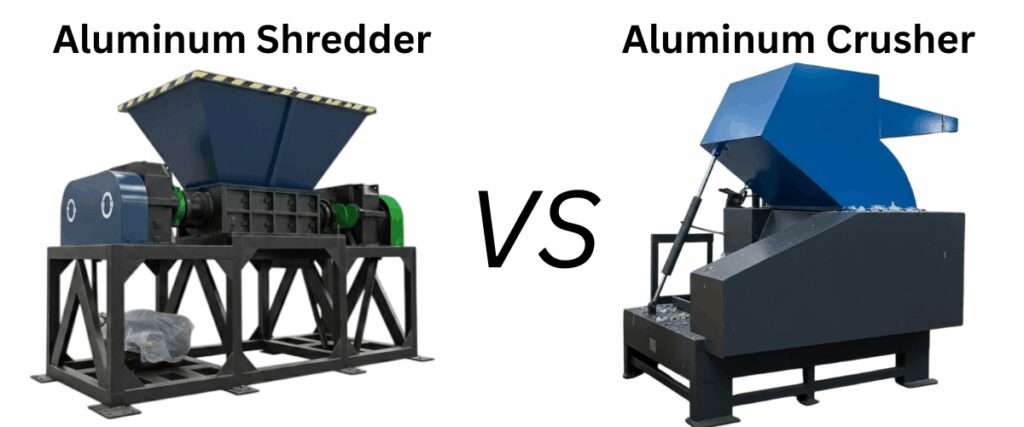

Aluminum Shredder vs Aluminum Crusher: Key Differences

While both machines perform the task of reducing aluminum waste, they do so in different ways. Here’s a breakdown of how an aluminum shredder vs aluminum crusher compares:

1. Method of Operation

- Aluminum Shredder: Uses rotating blades to cut and shred the aluminum into small chips. The cutting action is precise, which helps maintain the integrity of the material for reuse.

- Aluminum Crusher: Uses high-impact force or pressure to crush the aluminum. It’s typically more aggressive and results in fragmented pieces that are often flatter or irregular in shape.

2. Output Size and Quality

- Aluminum Shredder: The output from an aluminum shredder is typically uniform chips that are ideal for recycling. These chips can be easily melted down and repurposed into new products.

- Aluminum Crusher: The output from a crusher tends to be smaller, more fragmented pieces of metal. While this may be suitable for some types of recycling, it’s less uniform and can sometimes reduce the quality of the aluminum for future use.

3. Types of Material Processed

- Aluminum Shredder: Best suited for a variety of aluminum waste, including cans, profiles, scrap metal, and larger industrial parts. It’s versatile and effective on mixed aluminum waste.

- Aluminum Crusher: Typically used for crushing aluminum cans, small scrap pieces, and other lightweight materials. Crushers are ideal when the primary goal is to compact the material for storage or transportation.

4. Energy Efficiency

- Aluminum Shredder: Generally, more energy-efficient for processing a larger variety of materials. Shredders are designed to handle higher volumes with more consistency and less wear on the machinery.

- Aluminum Crusher: Crushers often use more energy to generate the high-impact force needed to break down tougher materials, making them less efficient than shredders in some cases.

5. Maintenance and Durability

- Aluminum Shredder: Requires regular maintenance, especially to the blades, but shredders are designed for long-term durability and can handle continuous operation without significant wear.

- Aluminum Crusher: Crushers often experience more wear and tear due to the intense force required to crush materials. They may require more frequent maintenance, particularly to the crusher plates or hammers.

When to Choose an Aluminum Shredder

An aluminum shredder is the ideal choice when you need to:

- Process a large volume of aluminum waste.

- Produce uniform, high-quality chips for reuse in manufacturing.

- Handle a variety of aluminum materials, including cans, profiles, and scrap.

- Prioritize energy efficiency and long-term operation.

When to Choose an Aluminum Crusher

An aluminum crusher is better suited for:

- Crushing aluminum cans or small scrap to reduce their size for easier handling and transportation.

- Applications where space reduction and compacting material are the primary goals.

- Environments where material is typically lightweight and doesn’t need to be preserved in chip form for recycling.

Aluminum Shredder vs Aluminum Crusher: Which is Right for You?

Ultimately, the decision between an aluminum shredder vs aluminum crusher comes down to your specific needs. If your goal is to recycle high-quality aluminum and produce reusable chips, a SHREDALLTM aluminum shredder will be the best option. SHREDALLTM shredders are designed for efficiency, durability, and versatility, making them perfect for processing various types of aluminum waste.

On the other hand, if you’re more focused on compacting aluminum for storage or transport, and don’t mind sacrificing the quality of the output, an aluminum crusher may be a more cost-effective choice.

At SHREDALL, we understand the importance of selecting the right equipment for your business, and we’re here to help you make the best choice for your needs. Whether you’re considering an aluminum shredder vs aluminum crusher, our team can provide the guidance and solutions that will help you streamline your recycling process and achieve the best results.

Conclusion

Both aluminum shredders and aluminum crushers offer distinct advantages depending on your specific recycling goals. If you need to produce high-quality, reusable aluminum chips, the precision and efficiency of a shredder are unmatched. However, if your focus is on compacting scrap for easier handling, a crusher might be the better fit.At the end of the day, choosing the right equipment comes down to understanding your business’s needs and the material you’re working with. Let SHREDALL help you make an informed decision, ensuring you get the right machine for maximum value and efficiency.