In the world of recycling, choosing the right shredder is crucial for maximizing efficiency, material recovery, and operational costs. For businesses handling aluminum scrap, understanding the difference between an Aluminum Profile Shredder and a Standard Shredder is essential to making the best choice for your operation. While both types of shredders perform similar tasks, they are designed for distinct purposes and offer unique advantages depending on the material you’re processing. This article will help you determine which shredder best suits your needs.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9820020714. Explore our Shredder range and get expert assistance.

What Is an Aluminum Profile Shredder?

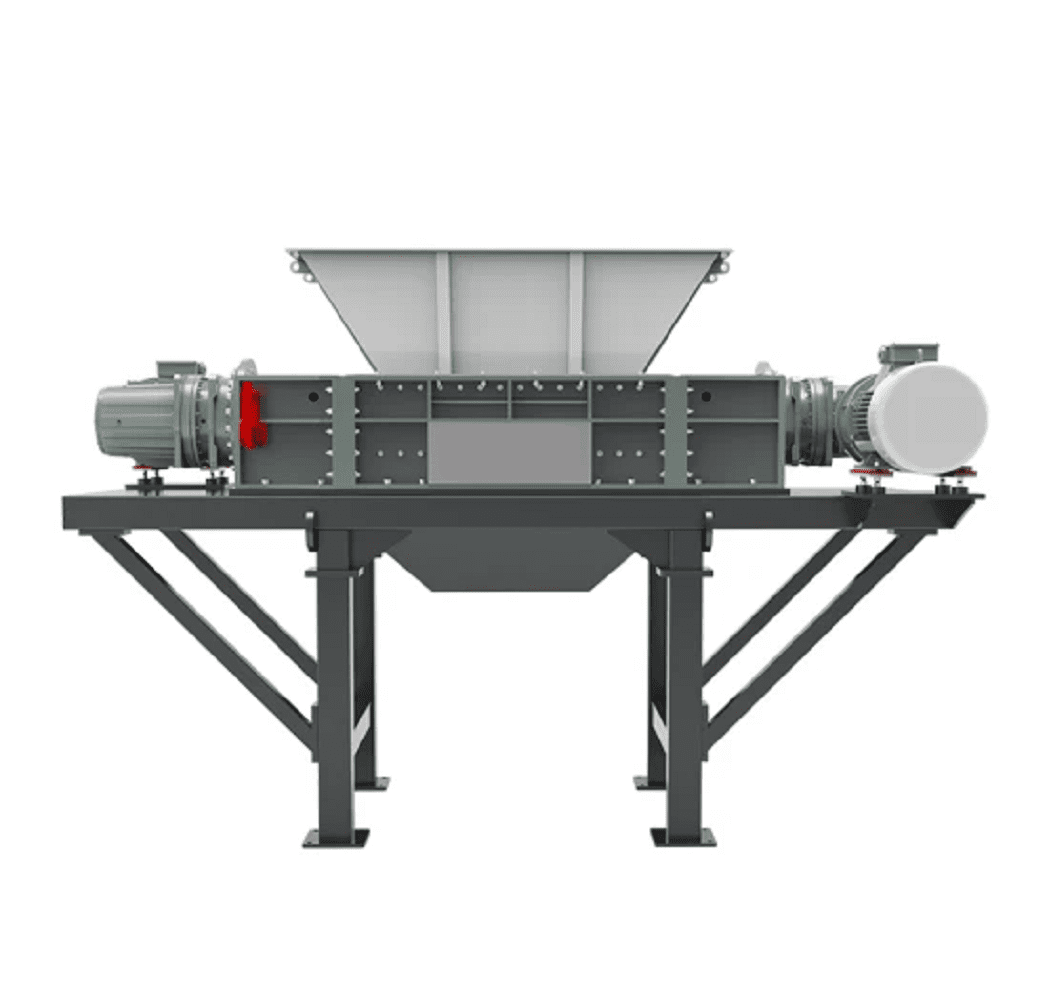

An Aluminum Profile Shredder is specifically designed to handle various forms of aluminum scrap, such as profiles, extrusions, and larger aluminum components often found in the construction, automotive, and manufacturing industries. These shredders are built with specialized features that allow them to efficiently process heavy-duty aluminum materials while maintaining high throughput and minimal wear.

Key features of an aluminum profile shredder include:

- Heavy-duty construction: Designed to handle large, tough aluminum profiles and extrusions without compromising performance.

- Optimized cutting technology: Tailored to reduce aluminum scrap into uniform pieces, making it easier to separate and recycle.

- Durability: Built with reinforced blades and robust components to withstand the wear and tear of processing metal.

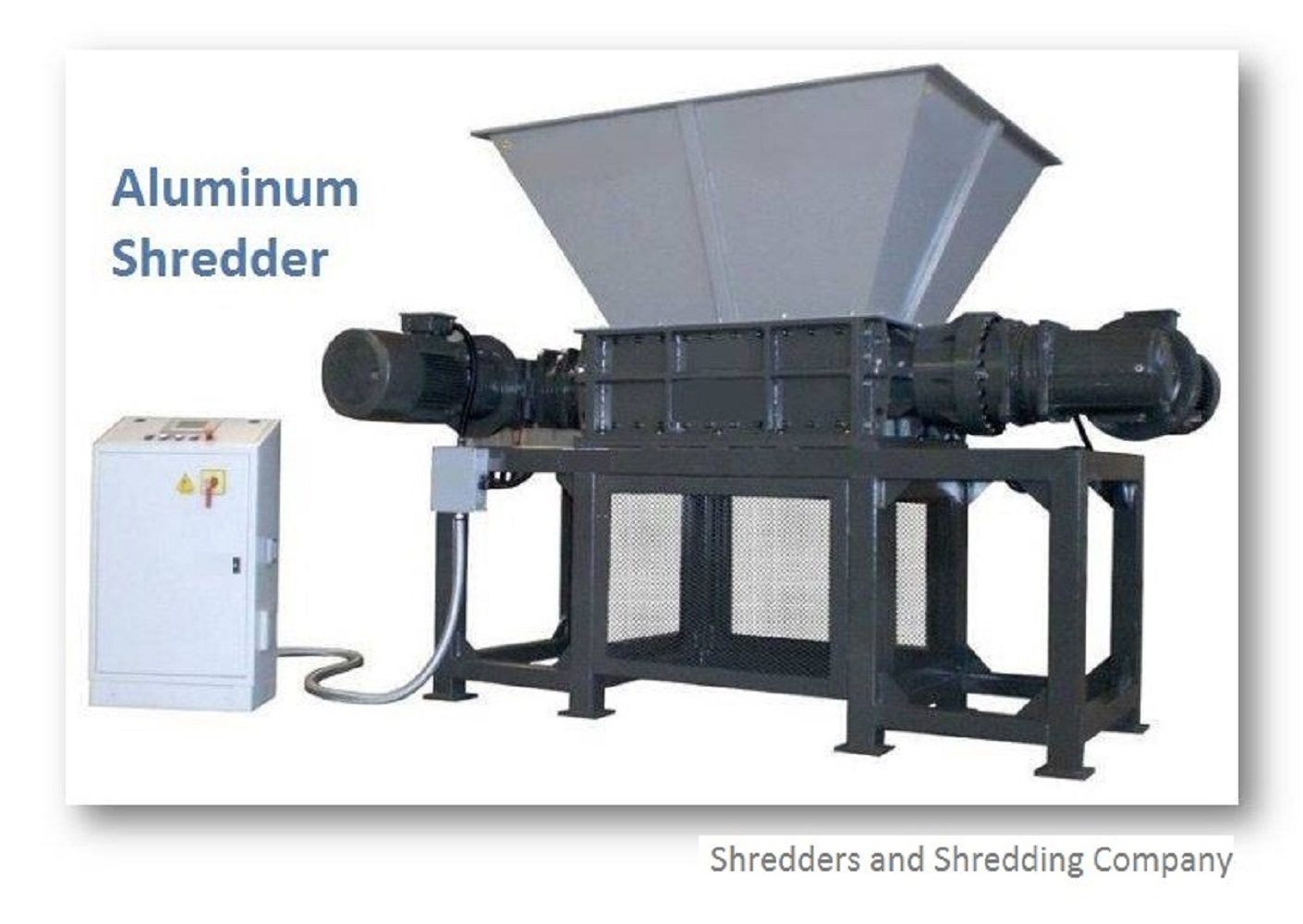

Aluminum Shredders

What Is a Standard Shredder?

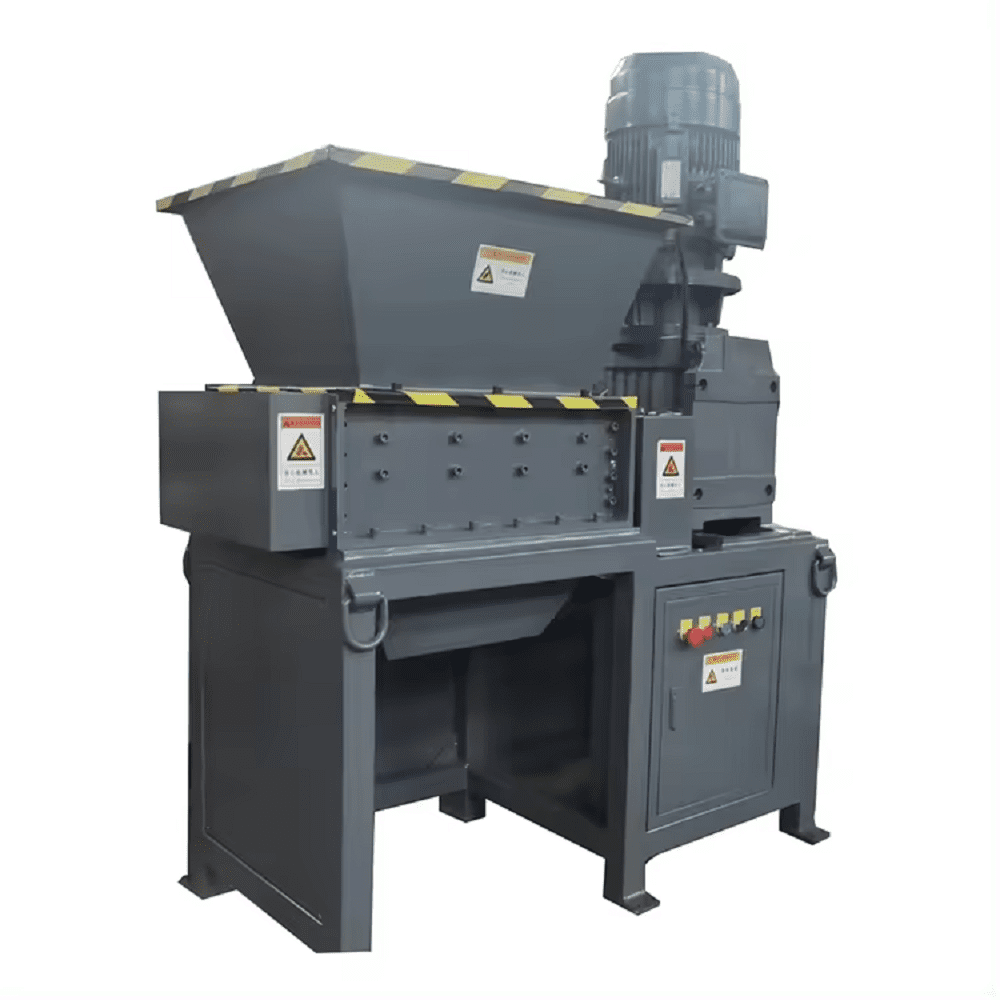

A Standard Shredder, on the other hand, is a more general-purpose shredding machine that can handle a wide variety of materials, including paper, plastic, wood, and some metals. While capable of shredding lightweight aluminum or small aluminum scrap, it is not specifically designed for the unique demands of processing larger aluminum profiles or extrusions.

Standard shredders are:

- Versatile: Suitable for a wide range of materials but may not be as efficient for heavy-duty aluminum scrap.

- Cost-effective: A more affordable option for businesses with diverse recycling needs but limited aluminum processing requirements.

- Less specialized: May struggle with larger or tougher aluminum materials, leading to increased wear and reduced efficiency.

Standard Shredders

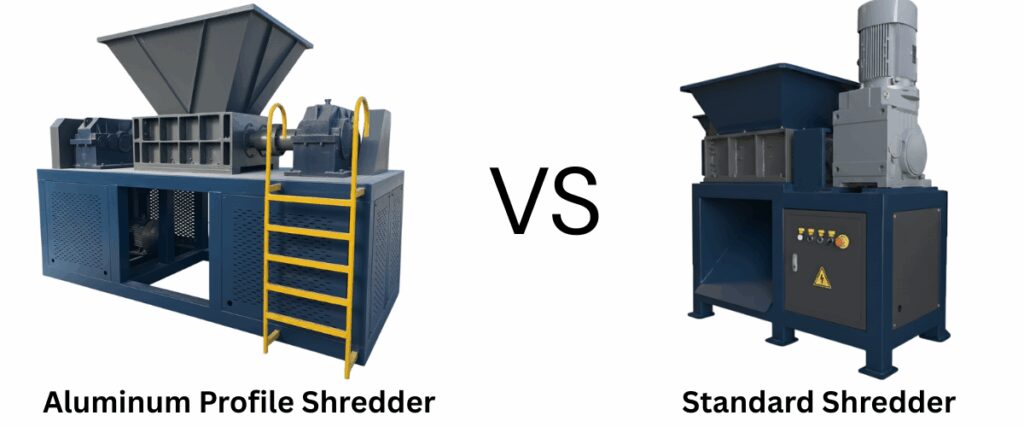

Key Differences Between an Aluminum Profile Shredder and a Standard Shredder

| Feature | Aluminum Profile Shredder | Standard Shredder |

| Designed for | Heavy-duty aluminum profiles and extrusions | General-purpose materials (paper, plastic, light metals) |

| Durability | High durability, reinforced for metal processing | Less durable when processing metal |

| Throughput | Higher throughput for aluminum scrap | Lower throughput for tough materials |

| Efficiency | Optimized for aluminum recovery | General efficiency for varied materials |

| Cost | Higher upfront cost due to specialization | More affordable for basic shredding tasks |

Which Shredder Is Right for You?

Choosing between an Aluminum Profile Shredder and a Standard Shredder depends largely on your specific recycling needs. Here are a few scenarios to help you decide:

- If you primarily handle aluminum profiles and extrusions:

An Aluminum Profile Shredder is the clear choice. Designed specifically to handle tough, large aluminum materials, this machine will ensure maximum efficiency and minimal downtime in your operations. - If you need a shredder for general-purpose recycling:

A Standard Shredder may be the better option, especially if your operations involve a wide range of materials and aluminum is just a small part of your recycling process. However, keep in mind that standard shredders may not handle larger or tougher aluminum scrap as efficiently. - If you’re looking for a cost-effective solution:

For businesses with limited aluminum scrap or lower volume, a Standard Shredder might be sufficient. It offers more flexibility for a variety of materials without the investment required for a specialized aluminum shredder.

Conclusion

Both Aluminum Profile Shredders and Standard Shredders have their place in the recycling industry. However, if your business specializes in processing aluminum scrap, investing in an Aluminum Profile Shredder will provide significant long-term benefits in terms of efficiency, durability, and material recovery. If aluminum is just one part of your material stream, or if you’re looking for a more versatile and cost-effective solution, a Standard Shredder might be the right choice.

Ultimately, the decision comes down to the type of materials you process most frequently and the specific demands of your recycling operation. By understanding the unique features and benefits of each shredder type, you can make an informed decision that best suits your needs, enhances operational efficiency, and boosts profitability.For businesses focused on optimizing aluminum recycling, SHREDALLTM Aluminum Profile Shredders offer superior performance and reliability, ensuring that your operation stays competitive in the growing recycling industry.