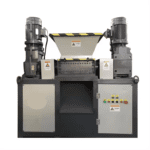

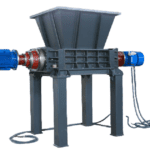

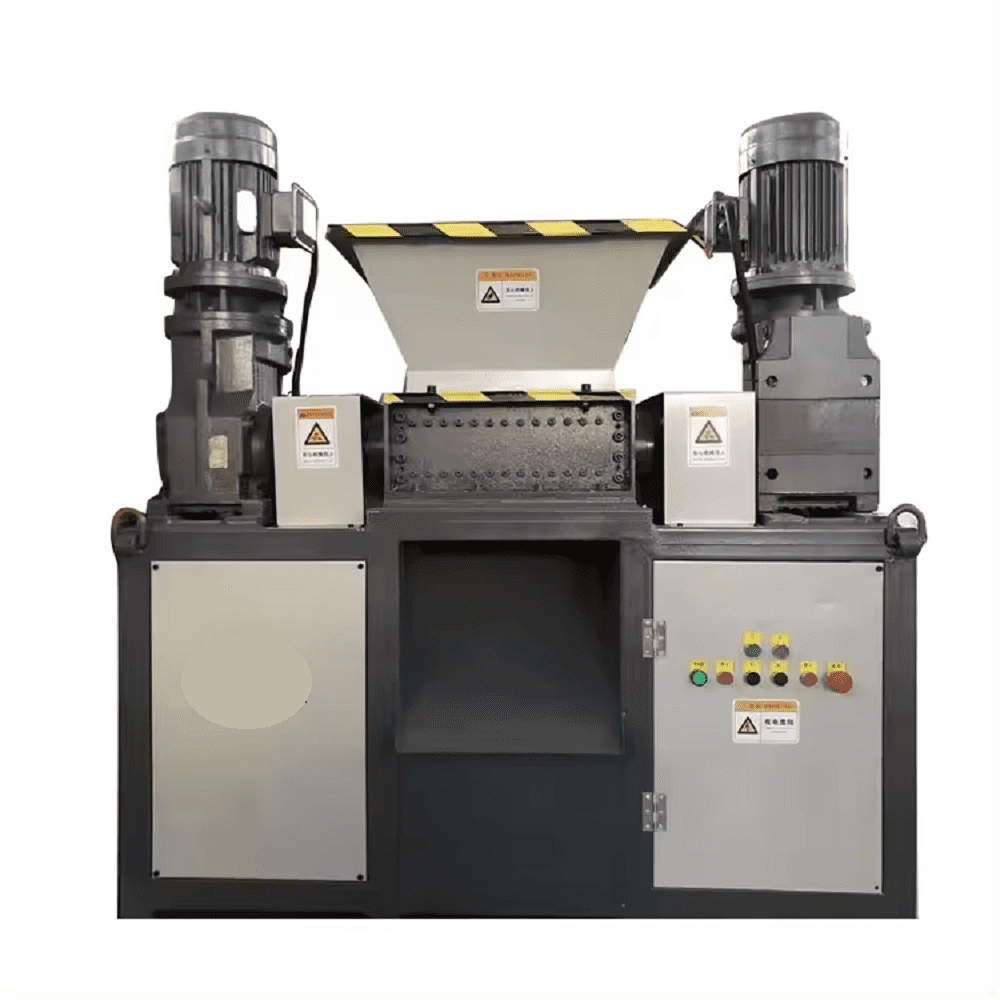

A scrap crushing machine is a piece of equipment used in recycling facilities to break down various types of scrap materials into smaller, more manageable pieces. These machines are crucial in the recycling industry as they help process scrap materials such as metal, plastic, glass, and more, turning them into reusable materials that can be used in manufacturing processes.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535 today to explore our range and get expert assistance.

A robust piece of equipment that transforms waste into valuable resources. One such industry leader in manufacturing these machines is SHREDALL. With an unparalleled commitment to quality, durability, and efficiency, SHREDALL’s machines are meticulously engineered to meet the diverse needs of the metal recycling industry.

Operational Efficiency and Noise Reduction

SHREDALL’s scrap crushing machines are designed for operational efficiency, producing low noise, sparking, dust, or heat rise. The unique cutter configuration of the SHREDALL® Industrial Shredder allows for efficient operation, making it an industry-standard metal shredder for any scrap metal recycling operation.

Key Features of Scrap Crushing Machine

Creating a profitable scrap crushing machine involves several considerations including efficiency, cost-effectiveness, durability, and versatility.

Automation and Control Systems

Implement automation and control systems to streamline operation and minimize human error. This can improve efficiency and reduce labor costs.

Shredding Machine Type

Scrap crushing machines are versatile tools, capable of handling a diverse range of applications:

Steel Drums

Whether empty or containing residual materials, these machines can efficiently shred steel drums.

Sheet Metal

Capable of processing sheet metal, these machines are suitable for recycling or disposal operations.

Metal Scrap

A common byproduct in various industrial processes can also be effectively dealt with.

Electronic Waste

Discarded electronic parts, such as hard drives and motherboards, are also within the capability of these machines.

Benefits of Using Scrap Crushing Machines

This Machine Many Benefits Incorporating a scrap crushing machine into a recycling operation can significantly enhance efficiency. These machines save time and reduce labor costs by automating the crushing process. Furthermore, converting metal waste into recyclable materials can potentially tap into new revenue streams while also contributing to environmental conservation.

SHREDALL’s Contribution to the Industry In India

For over 10 years, SHREDALL has been an industry leader in size reduction technology. Involving crushers, shredders, grinders, and more, SHREDALL ensures that their machines withstand the test of time and meet industry standards.

Automation Grade

The Shredder Machine is automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3-phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country’s manufacturing prowess.

Contact Us

We are here to assist you. Feel free to Contact us:

- Email: Info@shredall.in

Phone: +91 9090003535

Conclusion

Scrap metal recycling is an essential part of modern industrial operations. Using SHREDALL’s scrap crushing machines, industries can efficiently dispose of their metal waste, facilitating environmental sustainability and increasing profitability. The versatility, durability, and efficiency of these machines highlight the importance of choosing the right equipment for effective metal recycling.

In an era where waste disposal is an increasing concern, the proactive approach taken by companies such as SHREDALL demonstrates the potential for industries to contribute positively to the environment while also reaping the financial benefits of efficient waste management. Through the use of robust, efficient, and versatile scrap crushing machines, the metal recycling

Related Shredder

- Scrap Crusher MachineAt Shredall, we design and supply advanced recycling equipment, and one of our most efficient solutions is the Scrap Crusher Machine. This machine is specially… Read more: Scrap Crusher Machine

- Industrial Metal Scrap ShredderAt Shredall, we specialize in manufacturing and supplying high-performance shredding machines for industries across India and worldwide. One of our most trusted solutions is the… Read more: Industrial Metal Scrap Shredder

- Scrap Metal ShredderA Scrap Metal Shredder is a powerful machine designed to break down bulky metal waste into smaller, manageable pieces. For recycling companies, scrap yards, and… Read more: Scrap Metal Shredder

- Scrap Iron ShredderRecycling for Heavy Metal Waste A Scrap Iron Shredder is a powerful machine designed to process bulky iron scrap into smaller, uniform pieces for easier… Read more: Scrap Iron Shredder

- Industrial Steel Can Crusher MachineAn industrial steel can crusher is a must-have machine for businesses that handle large volumes of steel cans and metal waste. Unlike small, manual crushers,… Read more: Industrial Steel Can Crusher Machine

- Metal Crusher Machine PriceWhen it comes to managing metal waste, a reliable metal crusher machine is more than a tool, it’s an investment in efficiency and sustainability. At… Read more: Metal Crusher Machine Price

- Rolling Scrap shredderA Rolling Scrap Shredder, manufactured by SHREDALL, is a specialized, high-performance machine designed to shred various types of rolling scrap materials efficiently. This robust shredder… Read more: Rolling Scrap shredder

- All Scrap Crushing Machine for high profitsA scrap crushing machine is a piece of equipment used in recycling facilities to break down various types of scrap materials into smaller, more manageable… Read more: All Scrap Crushing Machine for high profits

- Waste Mild Steel Industrial Shredder MachineThe SHREDALL Waste Mild Steel Industrial Shredder Machine is the ultimate solution for efficient and robust waste management. Designed specifically for industrial use, this powerful… Read more: Waste Mild Steel Industrial Shredder Machine

- Automotive Part ShredderThe Automotive Parts Shredder by SHREDALL is a high-performance machine designed for the efficient shredding of automotive components. This robust shredder is engineered to handle… Read more: Automotive Part Shredder

- Steel Scrap Shredder MachineSHREDALL is a leading manufacturer of high-performance steel scrap shredder machines designed to process a variety of metal waste into reusable raw materials efficiently. Our… Read more: Steel Scrap Shredder Machine

- Scrap Metal Recycling Shredder MachineThe SHREDALL Scrap Metal Recycling Shredder Machine is a robust and efficient solution designed for shredding various types of metal scrap. It reduces large, bulky… Read more: Scrap Metal Recycling Shredder Machine