Top Aluminum Shredder: Premium Solutions from Shredall for Recycling & Waste‑Metal Processing

In the fast‑evolving world of metal recycling and waste‑metal processing, selecting the right equipment is crucial. At ShredallTM, we specialize in high‑performance aluminum shredders that set the benchmark in reliability, throughput, and return on investment. If you’re looking for the top aluminum shredders, you’ve come to the right place.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Key Value Of Top Aluminum Shredder

Aluminum is one of the most valuable scrap metals—lightweight, versatile and highly recyclable. But to unlock its full potential, you need equipment that can reliably handle the material and deliver consistent, clean output. Modern shredding machines do much more than just break metal down—they dramatically increase efficiency, lower costs, and contribute to sustainable operations.

- Shredded aluminum occupies far less volume, reducing transport and storage costs.

- Uniform piece size improves downstream processing (melting, refining) and helps improve material purity.

- Advanced shredders reduce downtime and maintenance costs, increasing throughput and profitability.

With Shredalltm range of top‑tier machines, recycling and waste‐metal operations can scale confidently and sustainably.

What Makes a Shredder One of the “Top” Models

When we say “top aluminum shredders”, we mean machines that excel across multiple criteria:

1. Capacity & Throughput

Top models handle a wide range of scrap volumes—whether smaller workshops or full‑scale recycling plants. Shredall offers machines with capacities from 500 kg/hr up to 5000 kg/hr to cover small, medium and large‑scale operations. shredall.in+1

2. Versatility in Scrap Material

The best machines handle everything from beverage cans and foil to heavy extrusions, profiles and castings. Shredall machines are designed for aluminum scrap of diverse types. shredall.in+1

3. Output Quality & Uniformity

Uniform particle size is key for efficient recycling. Top machines provide adjustable output size, clean cuts and minimal contamination.

4. Build Quality & Reliability

Shredding heavy metals demands robust construction. High‑quality materials, wear‑resistant components, solid drives and efficient maintenance keep operations running.

5. Efficiency & Sustainability

Modern shredders minimize energy consumption, reduce waste and support circular‑economy goals. Investing in a top shredder means lower operating cost and stronger environmental credentials.

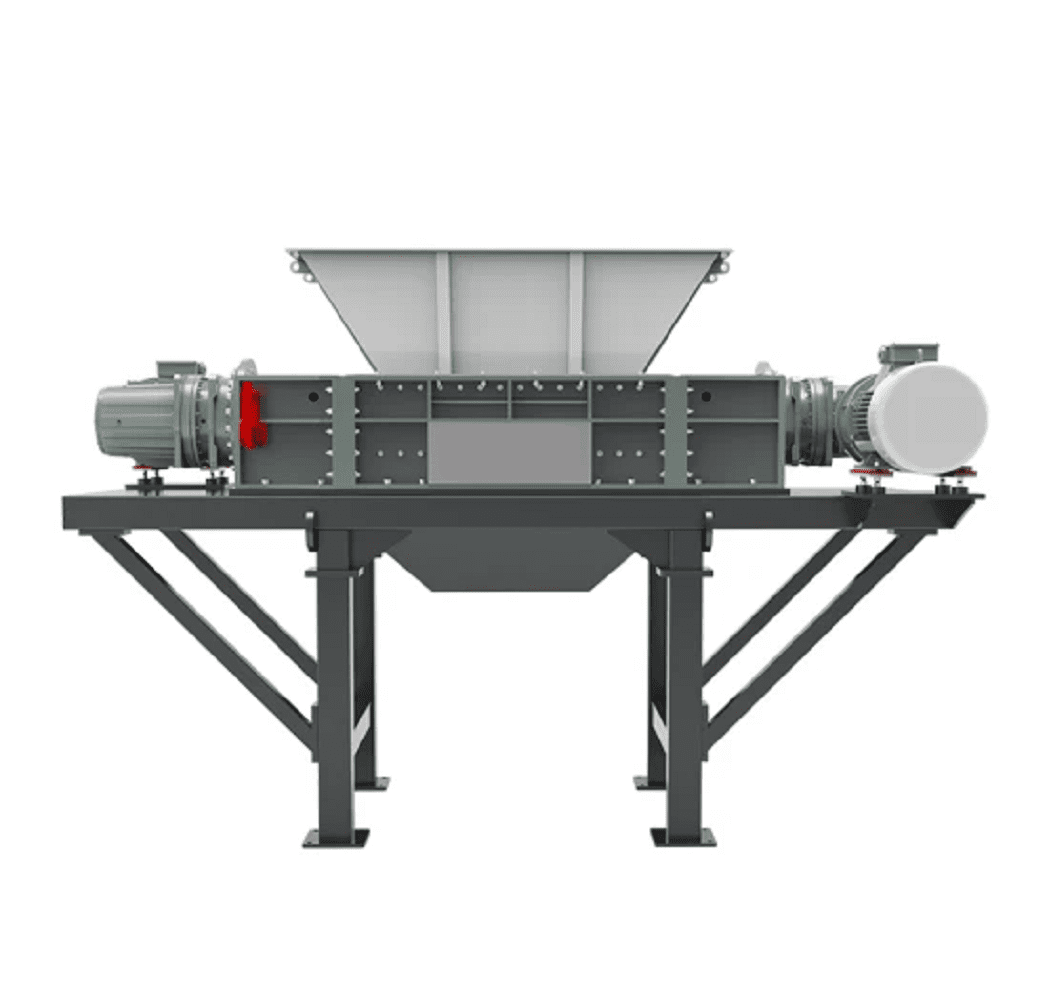

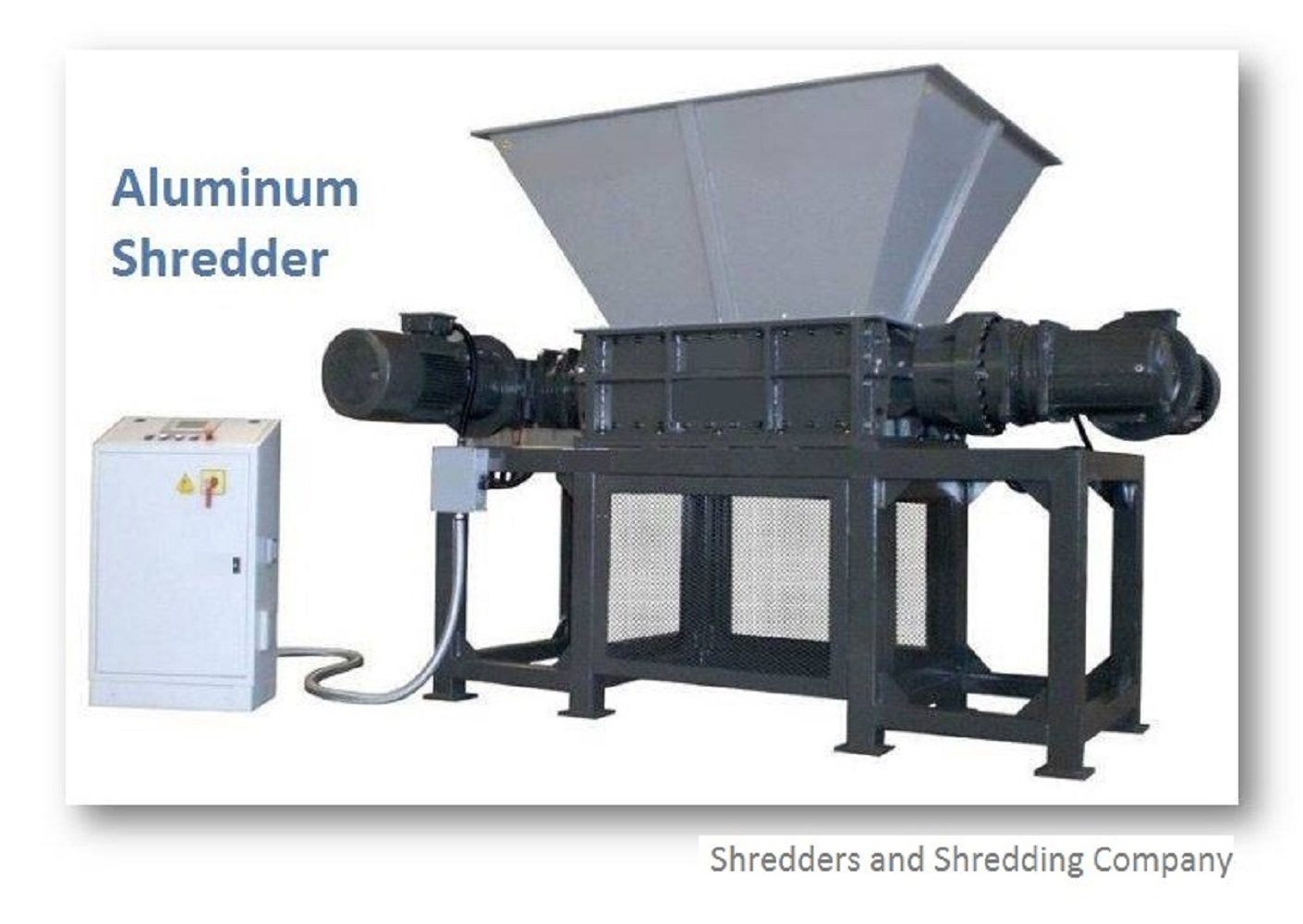

Aluminum Shredders

ShredallTM Leading Aluminum Shredders

At Shredall, we bring together all of the above in machines engineered for the real‑world demands of recycling and waste‑metal processing. Key highlights of our product line:

- Range of capacity options — From compact models to large‑industrial machines covering 500–5000 kg/hr. shredall.in

- Robust design — Built for continuous heavy use with minimal downtime. shreddersandshredding.net

- Ease of installation & operation — Designed for fast commissioning, simple operator interface, reliable maintenance. shredall.in

- Global shipping & support — We manufacture in India and deliver globally, giving you access to world‑class equipment at a competitive price. shredall.in+1

- Sustainability focus — Shredall machines help you reduce waste volume, minimize energy per ton and support resource recovery goals.

How to Choose the Right Model for Your Operation

Selecting the right shredder involves more than just picking the largest capacity. Here’s a practical selection guide to help you match ShredallTM machines to your specific needs:

| Step | Key Considerations | Shredall Tip |

| Define your scrap stream | What type of aluminium scrap do you handle? Cans, extrusions, castings, profiles? | Understand volume and types to choose a model optimised for your materials. |

| Determine output size requirements | Do you need fine chips for melting, or larger pieces for further processing? | Ask about screens, cutters and output size adjustability. |

| Match capacity to throughput | Know your daily/weekly tonnage and allow for future growth. | Choose a machine that covers current needs plus one step‑up for expansion. |

| Ensure infrastructure compatibility | Power supply (3‑phase), space, feed and discharge conveyors, dust extraction. | Shredall can support layout planning and technical checks. |

| Evaluate maintenance & lifecycle cost | Blade replacement cycles, energy consumption, downtime costs. | Ask for case studies and total cost per ton. |

| Consider vendor support & warranty | Installation, operator training, spare parts, after‑sales. | Shredall provides full support and global shipping. |

Real‑World Benefits for Recycling & Waste‑Metal Processing

By choosing a top aluminum shredder from Shredall, you stand to gain:

- Higher throughput — Process more scrap in less time, with fewer bottlenecks.

- Lower cost per ton — Reduced labour, transport volume, energy use.

- Better material quality — Cleaner, uniform output means higher value for recycled aluminum.

- Environmental advantage — Less landfill waste, lower carbon emissions, stronger circular economy alignment.

Why ShredallTM Should Be Your Partner

When you invest in a top aluminum shredder, you’re investing in a long‑term asset. Shredalltm delivers more than machines — we provide confidence, efficiency and service:

- Deep experience in aluminum scrap shredding and waste‑metal processing.

- Global manufacturing standards, made in India for competitive pricing.

- Full support network: installation, training, parts, service.

- Scalable solutions: whether you’re starting small or scaling up to industrial volume.

Ready to Choose Your Top Shredder?If you’re ready to elevate your recycling or waste‑metal operation, Contact Us Now. Let’s discuss your scrap profile, throughput needs, output requirements and budget. Together, we’ll choose the top aluminum shredder for your business — one that delivers performance, durability and profitability.