Battery Recycling Shredder: Turning Waste into Opportunity

Batteries—especially those in phones, laptops, power tools, and electric vehicles—contain valuable materials like lithium, cobalt, nickel, copper, and plastics. But when they end up in landfills, they can leak toxins, cause fires, and pollute the environment. A ShredallTM Battery Recycling Shredder helps solve this: it breaks down used batteries safely and efficiently so the materials can be recovered and reused.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Our Shredder Shreds All Kinds of Batteries with safety and separation

Having a shredder that can handle alkaline, lead-acid, lithium-ion, and nickel-cadmium batteries is a powerful tool in battery recycling. With the right safety, separation, and design features, such a machine turns hazard into resource. Shredall offers such a solution—ensuring safety, compliance, material recovery, and environmental responsibility—all in one shredding system.

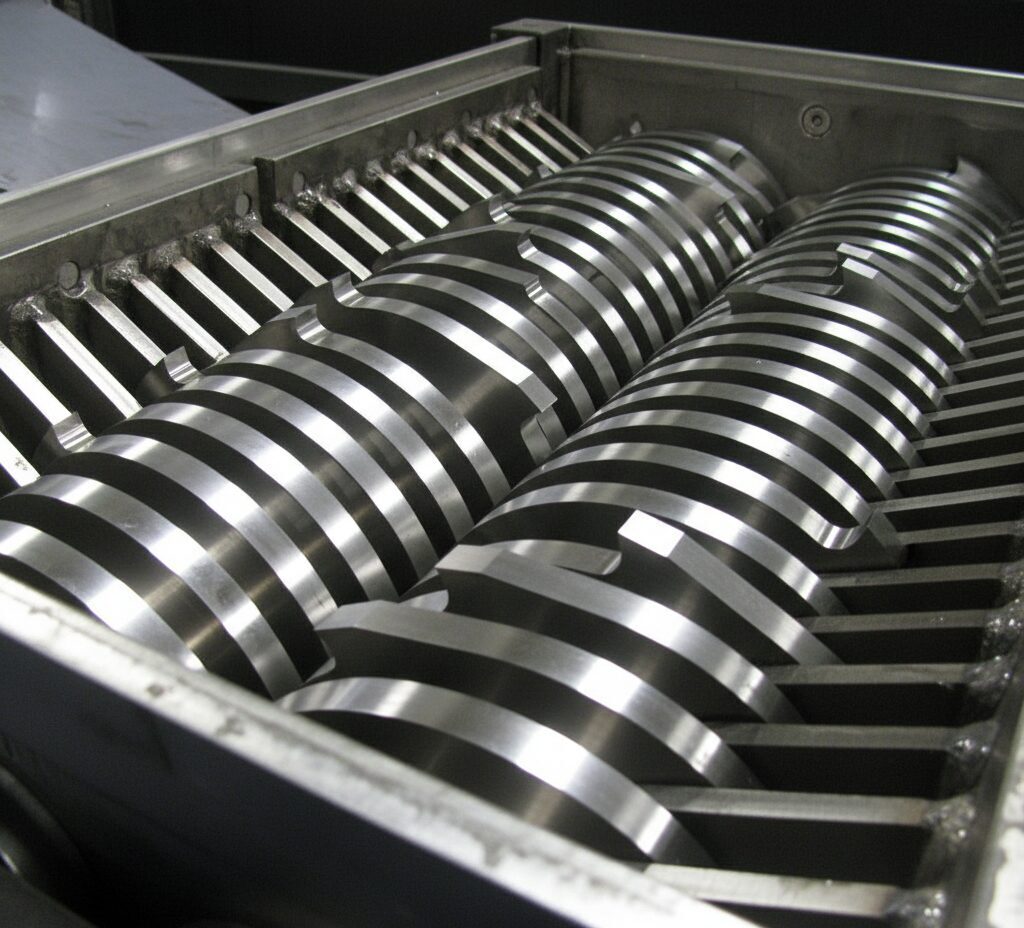

Battery shredder blades are made from hardened alloy tool steels, chosen for high wear resistance, toughness, and ability to endure heavy use without dulling quickly.

Why We Need Battery Recycling Shredders

- Environmental & Safety Risks: Batteries that aren’t correctly processed can pose dangers—fires, leaks of hazardous materials, and toxic pollution. For example, lithium-ion batteries are often classified as hazardous waste because of ignitability and reactivity.

- Growing Market Demand: The global market for battery recycling is expanding fast. From about USD 25.4 billion in 2024, it’s expected to reach nearly USD 70-70 billion by 2032, growing at over 13% CAGR. Also, battery materials-recycling (recovering metals and other components) is projected to grow heavily, from about USD 26.3 billion in 2022 to almost USD 57 billion by 2032.

- EV & Electronics Growth: More electric vehicles and more electronics mean more spent batteries every year. This increases pressure to properly recycle and handle end-of-life batteries.

How a Battery Recycling Shredder Works

- Collection & Pre-Treatment

Batteries are collected, sorted by type (e.g. lithium-ion, nickel-cadmium, lead-acid). Pre-treatment involves discharging them (removing as much stored power as possible), removing external casings or components, separating hazardous parts. This step is crucial for safety. - Shredding / Mechanical Breakdown

The shredder uses high torque shafts and hardened blades to tear apart the battery packs safely. It breaks open casings, separator layers, electrode foils, plastics—turning them into smaller, manageable fragments. - Separation & Recovery

After shredding, various separation methods are used:

- Magnetic separation to pull out ferrous metals (steel, iron).

- Eddy current or optical / sensor-based systems to recover non-ferrous metals like copper and aluminum.

- Screening / sieving to segregate different fragment sizes.

- Collection of “black mass”—the mix of electrode materials—for further chemical or metallurgical processing.

- Magnetic separation to pull out ferrous metals (steel, iron).

- Safety & Environmental Controls

Because batteries can still contain active chemicals, shredding must be done with proper containment, dust control, fire detection/suppression, and safe handling of fluids or electrolyte residues.

Key Features to Look for in a Good Battery Recycling Shredder & How ShredallTM Can Excel

A high-quality battery recycling shredder should have:

- Hardened, wear-resistant blades and shafts strong enough for battery casings and repeated use.

- Low-speed, high-torque design to minimize risk of sparks and overheating.

- Separation modules to sort metal, plastics, and hazardous parts.

- Easy maintenance (blade replacement, accessible parts), good after-sales service.

ShredallTM is well positioned to build shredders with all these features—machines that safely process large volumes of battery waste, provide high material recovery, and ensure compliance with safety and environmental norms.

Benefits of Using a Battery Recycling Shredder

- Recover valuable metals & reduce the need for mining new ore.

- Reduce environmental hazards, prevent battery‐fires, toxic leaks.

- Lower waste handling and transportation costs (small fragments easier to move).

- Help companies meet regulatory and safety requirements.

- Generate revenue from selling recovered materials and possibly through government incentives for recycling.

Conclusion

Battery waste is one of the fastest growing challenges of modern electronics and green technology. A good battery recycling shredder can turn that challenge into an opportunity: safer handling, cleaner environment, and recovered materials. With solid design, safety systems, and efficient separation, machines from brands like Shredall can be central to sustainable battery recycling—keeping electronics alive in circular supply chains instead of landfills.