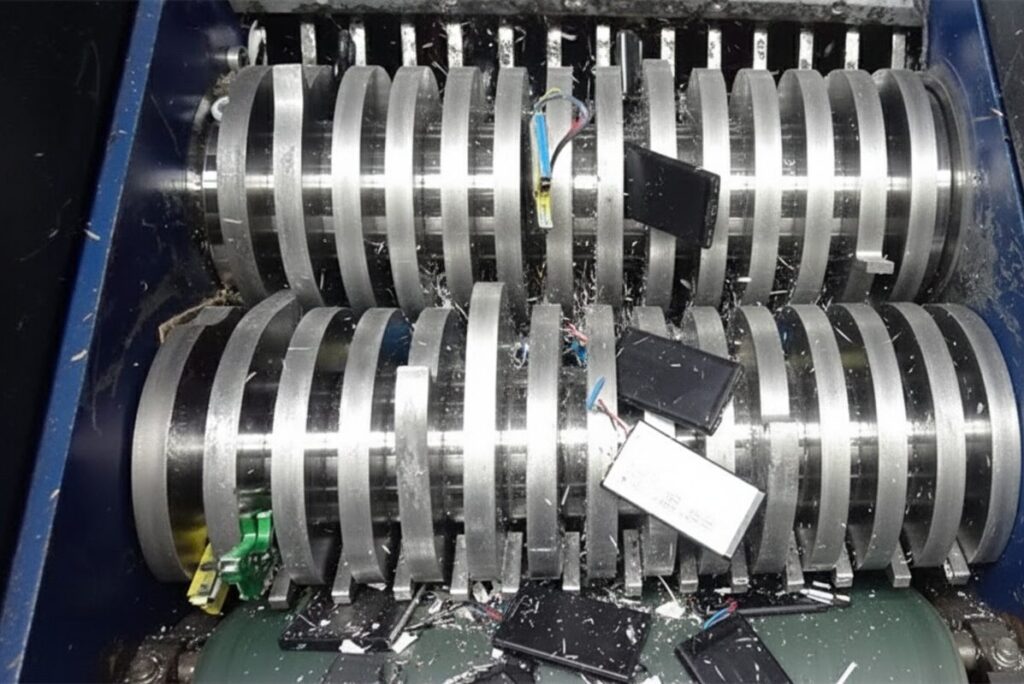

Mobile Battery Shredder by Shredall: Safe, Efficient, and Responsible Recycling

As mobile devices proliferate, batteries—especially lithium-ion types—are accumulating rapidly in waste streams. The Shredall Mobile Battery Shredder offers a solution built for safety, performance, and sustainability. Designed to process used mobile batteries, power-packs, and related modules, it ensures materials are recovered without compromising safety or the environment.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Key Features & Technical Considerations

- Pre-Discharge & Sorting

Before shredding, batteries are fully discharged. This eliminates residual charge that could cause short-circuits or thermal runaway during processing. Batteries are sorted by type (cylindrical, pouch, prismatic) because different chemistries behave differently under stress. - Robust Mechanical Design

ShredallTM uses hardened alloy blades and a dual-shaft high-torque motor system to break through tough casing, separators, foils, and metallic collectors. Low-speed, high-force cutting reduces generation of sparks and inhibits overheating. Drum geometry and feed design help ensure steady flow without jams. - Safety Systems & Fire Mitigation

A tight enclosure ensures that if any cell ruptures or vents, hazardous gases and heat are contained. In some industrial systems, inert atmospheres or water spray are used to dampen combustion risk. (Sources note that risks increase when batteries aren’t fully discharged or when shredding happens in open airflow.

- Separation & Recovery Process

After shredding, fragments pass through magnetic separators (for ferrous metal), eddy-current or optical systems (for non-ferrous), and screens to sort plastics, separators, and electrode materials. The goal is to recover lithium, cobalt, nickel, copper, aluminium, and other metals cleanly. Dry shredding under controlled atmospheres helps avoid fires; water spray or liquid cooling is sometimes employed.

Challenges & Risk Management

- Thermal Runaway & Fire Risk: When cells are shredded while still charged, exposed internal materials like foils and electrolytes may generate heat or sparks. Fully discharging is vital. Studies show that electrolytes decompose at elevated temperatures (>80°C), releasing flammable gases.

- Toxic Gas Emission & Corrosion: Shredding can release organic solvents or acidic gases. Blade materials and chamber linings must be resistant to corrosion; seals must maintain atmosphere control.

- Material Separation Complexity: Electrode binders, separator films, current collectors are tightly bonded. Black mass (the active material) often requires downstream chemical / hydrometallurgical treatment. Efficient shredding yields size fragments that allow better separation.

Benefits of ShredallTM Approach

- High Material Recovery: Metals like lithium, nickel, cobalt, copper, aluminium are reclaimed. This conserves resources and reduces demand for new mining.

- Reduced Waste & Carbon Footprint: Shredded volume is smaller; less landfill, lower transport cost. Less CO₂ emissions than mining and raw material extraction. (Recycling lithium-ion batteries is more energy-efficient than mining virgin metals.

- Scalable Solutions: ShredallTM designs units for small e-waste centers up to large industrial installations. Users can scale capacity, choose appropriate blade design and separation modules.

Applications

- E-waste recycling centers handling used phones, tablets, and small electronics

- Mobile repair shops and refurbishment units disposing of defective or end-life batteries

- Producers and suppliers with battery waste (laptop, EV battery modules, power banks)

- Suppliers of electronics wishing to ensure secure, safe, and environmentally responsible disposal

Conclusion

The ShredallTM Mobile Battery Shredder brings together engineering, safety, and environmental responsibility. By emphasizing full discharge, robust mechanical design, advanced safety controls, and efficient separation, it addresses the major risks of lithium-ion battery recycling. In a growing e-waste world, this shredder helps industries protect people, comply with laws, and recover value—all in a sustainable way.