Engine and gearbox parts contain some of the densest and most valuable metals in vehicles—cast iron, aluminium alloys, hardened steels, and copper. An Engine & Gearbox Parts Shredder is a specialized machine built to deal with these hard materials. It breaks them down into salvageable fragments so recyclers, foundries or smelters can extract metals efficiently. For brands like Shredall, we offer a shredder that handles engine and gearbox components with precision, durability, and high throughput is a distinguishing advantage.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Why These Parts Are Challenging & Why Shredding Helps

- Material Density & Durability: Engine blocks, cylinder heads, gear cases, shafts and synchronizers are made with thick walls, robust castings, and hard surfaces to endure high stress and heat during operation. Shredding them requires very high mechanical force, good blade hardness, and strong drive systems.

- Mixed Metal Content: These components often combine multiple metals (e.g. steel and aluminium in an engine’s casing, with copper or brass in bearings). Proper shredding and subsequent separation lets recyclers capture the full value of all these metals instead of sending them to landfill or low-grade scrap.

- Hazardous Components: Gearboxes may contain residual oil or lubricants. Engines often have oil, coolant, and sealed components. Pre-processing (draining fluids, removing non-metal parts) is necessary to comply with safety, environmental laws, and to protect shredding machinery.

- Volume & Transport Savings: Whole engines or gearbox units are bulky, heavy, and inefficient to store or transport. Shredding reduces volume dramatically, makes material easier to handle, and lowers freight costs.

Key Design Features of an Effective Engine & Gearbox Parts Shredder

| Feature | What You Need for Engine/Gearbox Parts |

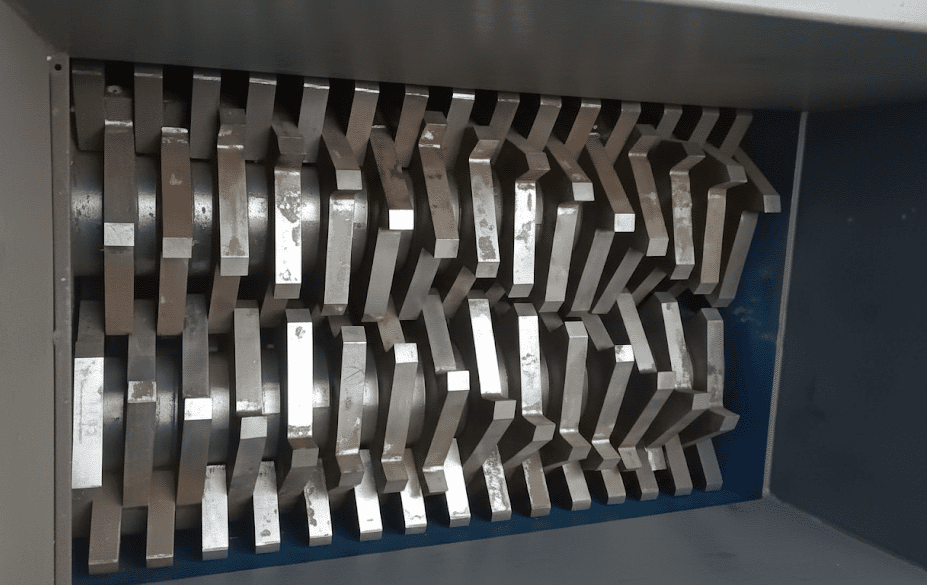

| High Torque, Low Speed Shafts | To power through thick metal without overheating or stalling. Dual-shaft or multi-shaft shear designs are beneficial. |

| Hardened, Wear-Resistant Blades / Cutters | Use high-grade alloy steel, possibly with surface treatment, to resist abrasion and impact. |

| Robust Frame & Bearings | Shredding dense parts subjects machinery to shock loads; strong support, reinforced frames, high-quality bearings are essential. |

| Effective Separation Systems After Shredding | Magnetic separation for ferrous metals; eddy current or sensor/optical systems for aluminium, copper; screening to get uniform particle size. |

| Safety & Environmental Controls | Fluid containment (oils, greases), dust suppression, safety guards, noise control, regulatory compliance. |

| Control & Monitoring | Blade wear sensors, overload protection, torque monitoring, reverse feed or jam clearing mechanisms. |

Example Technologies & Machines in Use

- Engine Block Crusher: Some systems use hydraulic extrusion or pressing where a block is forced into a chamber with great force, causing cracks, fractures, and breaking into pieces. These machines can reduce engine block size by over 60-70%.

- Double-Shaft Shredder: Designed with two counter-rotating shafts fitted with high-strength blades. Excellent for cast iron parts from engines and gearbox housings. Produces uniform shredded fragments that are easier to sort and melt.

- Motor & Gearbox Recycling Lines: Some plants (for example, motor recycling plants in Italy) integrate crushing, separation (deferrization), and separation for various metals, including cast iron, steel, and aluminium. These custom lines are sized to customer needs.

Applications & Industries that Benefit

- Metal recycling scrapyards that handle automotive scrap

- Automotive dismantlers wanting to extract maximum metal value from engines/gearboxes

- Foundries & steel mills using scrap feedstock

- Government or industrial facilities focused on ELV (End-of-Life Vehicle) recycling

- Dealers of non-ferrous metals (aluminium, copper) who want separated, clean shredded inputs

Benefits of Investing in a High-Quality Engine & Gearbox Parts Shredder

- Maximized Metal Recovery: More ferrous and non-ferrous metals recovered cleanly, increasing revenue.

- Reduced Waste / Better Purity: Less contamination from oils, plastics, fluids; means higher value metals and fewer impurities.

- Lower Operating Cost Over Time: Better machines that endure are cheaper in maintenance and downtime.

- Environmental Compliance: Safe handling of lubricants, oils; proper filtration of dust; meeting regulations.

- Efficiency & Throughput: The right shredder will break down parts faster, allowing higher throughput per hour.

Key Challenges & How to Overcome Them

| Challenge | Solution / Mitigation |

| Very hard materials causing blade wear | Use of hardened steel alloys; blade profiling; frequent inspection & replacement; cooling or lubrication where possible |

| Mixed materials & residual oils causing smoke or damage | Pre-treat parts to remove fluids; use of housing or inlet designs that limit fluid splash; proper sealing/dust control |

| High energy consumption | Use high-torque but efficient drive systems; variable frequency drives (VFDs); slow speed, high torque designs |

| Machine costs & capital investment | Modular design so capacity can scale; financing/leasing; showing ROI via metal recovery & savings in transport / handling costs |

| Environmental / safety regulation requirements | Include features for oil containment; emission / dust filters; compliance certifications; trained operators |

Why a Shredall Makes a Difference

A brand like Shredall that designs its engine & gearbox parts shredder with the features above robust blades, high torque, effective separation, safety standards—will:

- Deliver longer service life, reducing the cost per ton shredded.

- Provide cleaner output, commanding higher prices for separated metal fractions.

- Offer warranties, spare part availability, local service, which reduce downtime.

- Help recyclers meet regulatory and environmental compliance more easily.

Conclusion

Engine and gearbox parts are challenging material, but also among the most valuable. A purpose-built shredder with the right design, durability, and after-sales support turns what would otherwise be waste into recovered value. For recycling plants, automotive dismantlers, and metal recovery operations, investing in a high-performance engine & gearbox parts shredder isn’t just smart—it’s essential for profit, sustainability, and competitiveness.