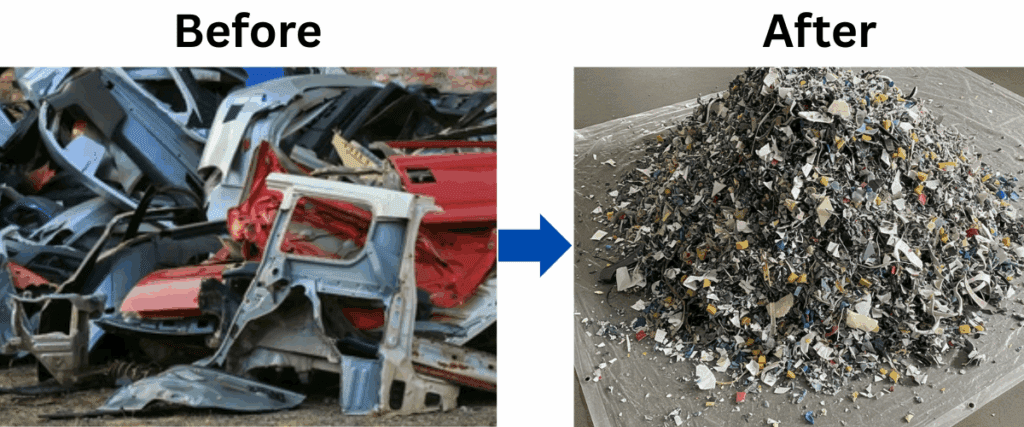

Every year, millions of vehicles reach the end of their useful lives. Once they stop serving on roads, car bodies become bulky, hazardous, and full of materials that, if not handled properly, damage the environment. A car scrap shredder is the machine that changes all that: it rips apart car hulks into manageable, recyclable fragments. This process saves space, reduces pollution, and recovers metals worth millions. In this article, we explore how car scrap shredders work, why they’re becoming essential, what features to look for, and how they’re shaping the future of recycling.

👉 Contact Us Email: Info@shredall.in, Phone: +91 9090003535. Explore our Shredder range and get expert assistance.

Market Opportunity & Why Now

- Growing Indian Metal Recycling Market: The metal recycling market in India was valued at over USD 11.40 billion in 2024, and is expected to reach nearly USD 18.87 billion by 2033, with a CAGR of ~5.3%. IMARC Group

- Non-Ferrous Scrap on the Rise: Demand for aluminium, copper, and other non-ferrous metals is increasing fast; their recycling market is growing at ~6-7% CAGR. Grand View Research+1

- Environmental & Regulatory Push: Government policies in India are pushing for sustainable waste management, circular economy practices, and stricter norms for end-of-life vehicle (ELV) handling. This means more formal scrap collection, higher expectations for metal recovery, and greater incentive to use high-quality shredding machinery. IMARC Group+1

With growth in supply of scrap car bodies, rising metal prices, and regulatory pressure, investing in a robust car scrap shredder makes commercial sense — and Shredall is here to deliver that solution.

How the Shredall Car Scrap Shredder Works

Shredding Process

- The car body is moved into the shredding chamber.

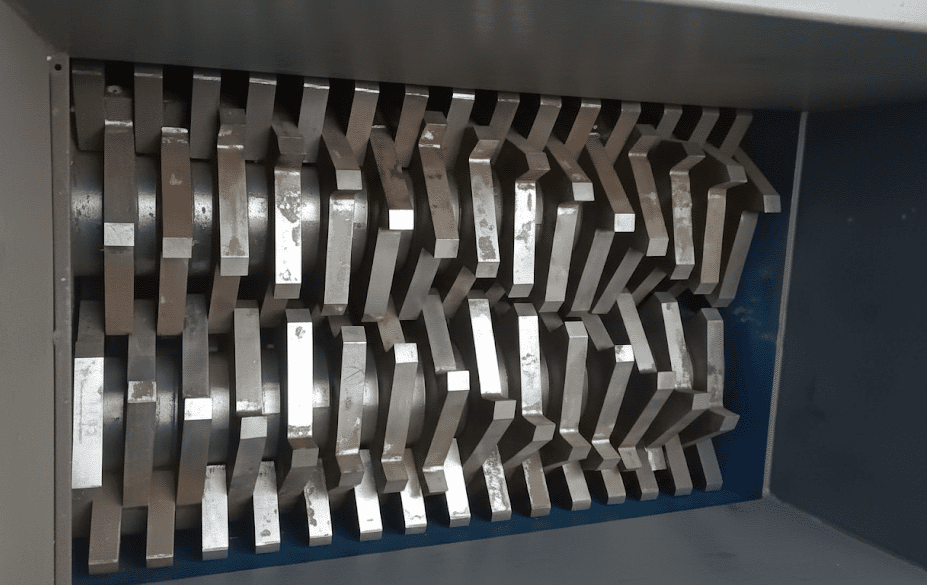

- Powerful shafts with high-grade, heat-treated blades shear, crush, and tear metal components. Shredall uses hardened steel blades capable of handling thick panels, frames, and mixed metals without frequent slowing or damage.

Separation & Sorting

- Magnetic Separation: Ferrous metals (steel, iron) are separated from shredded output.

- Non-ferrous Recovery: Eddy-current separators or sensor/optical systems pull out aluminium, copper, and other valuable metals.

- Output Sizing: Screens or mesh ensure output pieces are uniform, helping downstream melting or smelting operations.

Discharge & Post-Processing

- The processed metal fragments are discharged via conveyor or chute.

- Waste such as plastic, rubber, glass is collected for proper disposal or reuse.

- Monitoring systems record metrics such as motor load, blade wear, throughput, allowing for predictive maintenance and minimizing downtime.

Key Features that Define Shredall Car Scrap Shredder

| Feature | How Shredall Excels |

| Robust Blades & Build | Blades manufactured from wear-resistant, heat-treated alloy steel; reinforced shredder chamber to resist impact and fatigue. |

| High Torque & Power Ratings | Motors and gearboxes designed to deliver enough force to shred whole car shells without stalling. |

| Safety & Environmental Controls | Fluid capturing, dust suppression, safety interlocks, sound insulation come built-in. |

| Efficient Separation | Magnetic and non-ferrous separation systems to maximize metal recovery and purity. |

| Ease of Maintenance & Support | Shredall offers warranty, replacement parts, local service support, training. Machines designed for easy blade replacement and inspection. |

| Cost-Efficiency | Lower operating cost due to energy optimization and durable components; high metal recovery rates reduce raw material cost and increase profit margins. |

Applications of the Shredall Car Scrap Shredder

- Recycling of end-of-life vehicles (ELVs) — car bodies, trucks, old buses.

- Salvage yards & auto dismantlers removing value before shredding.

- Steel & aluminium foundries using shredded metal as input feed.

- Government or municipal vehicle scrappage centers.

- Industrial plants with metal waste from manufacturing, repair, or demolition.

Benefits You Get with Shredall

- High Metal Recovery Rates: Up to 90-95% recovery of metals (ferrous + non-ferrous) from a shredded car body.

- Significant Volume Reduction: Reduces bulky scrap size, cutting transportation & storage costs.

- Reduced Labour Costs: More automation, less manual dismantling and manual handling once process starts.

- Lower Environmental Impact: Safely handles hazardous components, reduces landfill burden.

- Regulatory Compliance & Reporting: Meets environmental & safety standards; Shredall provides documentation & support for compliance.

- Return on Investment (ROI): Payback period shortened due to savings on scrap volume, recovered material value, reduced downtime thanks to reliable components.

Challenges & How Shredall Addresses Them

| Challenge | Shredall’s Solution |

| Inconsistent scrap input / Mixed materials | Pre-processing modules & separation systems upstream ensure consistent feed and remove contaminants. |

| Blade wear & machine downtime | Use of hardened steel blades + predictive monitoring to plan maintenance; spare parts kept in stock. |

| High energy consumption | Optimized drive systems; variable speed drives; design for torque efficiency. |

| Environmental compliance | Waste fluid capture, emissions control, worker safety measures built-in. |

Industry Trends & Future Growth

- The metal recycling market in India is growing at ~5-6% CAGR. As more vehicles retire and ELV policies strengthen, the supply of scrap car bodies will increase. Grand View Research+1

- Non-ferrous metal recycling (aluminium, copper) is expanding more than ferrous in some sectors because of high value and demand. Grand View Research+1

- Incentives from government for critical mineral recycling and ELV handling will help formalize the sector and push more businesses to use quality shredders. Outlook Business+2IMARC Group+2

Why Choose Shredall Over Others

- Made with Indian engineering and global standards.

- Full warranty and after-sales support — spare parts, technician help, training.

- Competitive pricing without compromising on quality.

- Proven track record in India and exports.

- Customization options: shredder size, output size, blade type, power specifications — we adapt to your needs.

Conclusion

If you’re in the metal recycling business, vehicle dismantling, auto salvage, or government/municipality waste management, the Shredall Car Scrap Shredder is a best choice investment. It combines performance, durability, efficiency, and environmental responsibility. As India’s metal recycling sector expands rapidly, choosing the right shredder now gives you a competitive advantage, better margins, and helps build a sustainable future.